eBook - ePub

Membrane Engineering for the Treatment of Gases

Volume 1: Gas-separation Issues with Membranes

This is a test

- 293 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

Membrane Engineering for the Treatment of Gases

Volume 1: Gas-separation Issues with Membranes

Book details

Book preview

Table of contents

Citations

About This Book

Elaborating on recent and future developments in the field of membrane engineering, Volume 1 focuses on new membrane materials which have recently emerged in gas separation. Covering graphene/graphene oxide based membranes, PIMs, thermally rearranged membranes, and new mixed matrix membranes, alongside membrane pilot plant trials of gas separation, such as CO2 from flue gas and biogas, as well as a cost analysis of competitive membrane and hybrid systems, this book provides a comprehensive account. Together with Volume 2, these books form an innovative reference work on membrane engineering and technology in the field of gas separation and gaseous phase membrane reactors.

Frequently asked questions

At the moment all of our mobile-responsive ePub books are available to download via the app. Most of our PDFs are also available to download and we're working on making the final remaining ones downloadable now. Learn more here.

Both plans give you full access to the library and all of Perlego’s features. The only differences are the price and subscription period: With the annual plan you’ll save around 30% compared to 12 months on the monthly plan.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 1000+ topics, we’ve got you covered! Learn more here.

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more here.

Yes, you can access Membrane Engineering for the Treatment of Gases by Enrico Drioli, Giuseppe Barbieri, Adele Brunetti in PDF and/or ePUB format, as well as other popular books in Physical Sciences & Industrial & Technical Chemistry. We have over one million books available in our catalogue for you to explore.

Information

CHAPTER 1

Modelling of Gas Separation in Thermally Rearranged Polymeric Membranes

a Institute on Membrane Technology (ITM-CNR), National Research Council, c/o The University of Calabria, Cubo 17C, Via Pietro Bucci, 87036 Rende CS, Italy

b The University of Calabria – Dept. of Environment and Chemical Engineering, Via Pietro Bucci, Cubo 44A, 87036 Rende CS, Italy

c Department of Energy Engineering, College of Engineering, Hanyang University, Seoul, 133-791, South Korea

*E-mail: [email protected]

1.1 Introduction

The sustainable development of chemical and related process-oriented industries critically depends on the development of new innovative processes that use materials and energy more efficiently.1,2

The development of advanced membrane technologies and the industrial application of polymeric membranes require good understanding of the materials properties and their transport mechanisms, as well as the realisation of innovative functional materials with enhanced properties. Those different aspects have been discussed in detail in previous lectures and have been recently reviewed in the literature.3–5

Membrane separation technologies have profited from the progress in materials research and processing for device technologies. In particular, membranes for gas separation made mainly of polymer materials, owing to their easy processability and good mechanical properties, compete with other separation processes such as cryogenic distillation and adsorption due to their easy operational handling, relatively small size, low energy consumption, and space efficiency.

Breakthroughs in the development of highly permeable materials for membranes are essential. In this context, microporous polymers are considered efficient membrane materials and good candidates to overcome the well-known Robeson’s upper bound.6 Specific tailoring of the molecular structure can be regarded as a viable approach to obtain improvements on membrane permselectivity due to (i) the loss of inter-segmental packing with a simultaneous inhibition of the intra-segmental (backbone) mobility, and (ii) the weakening of inter-chain interactions (reduction of charge transfer complexes).7

Recent progress in the development of microporous polymers as gas separation membranes has been achieved by improving the rigidity of the entire polymer structure to improve the separation performance, since a rigid polymer structure enhances the separation properties and durability of the membranes used for gas separation and storage materials.8

Thermally rearranged (TR) polymers are an example of microporous polymers with high permeability and selectivity for the separation of gas mixtures.9–12 In particular, they have shown outstanding molecular and ionic transport, as well as separation performance, beyond the limits of more conventional polymers.13–16

An example of process design using TR polymer membranes can be found in the work of Dong et al. from 2015.17

1.1.1 Thermally Rearranged (TR) Polymers

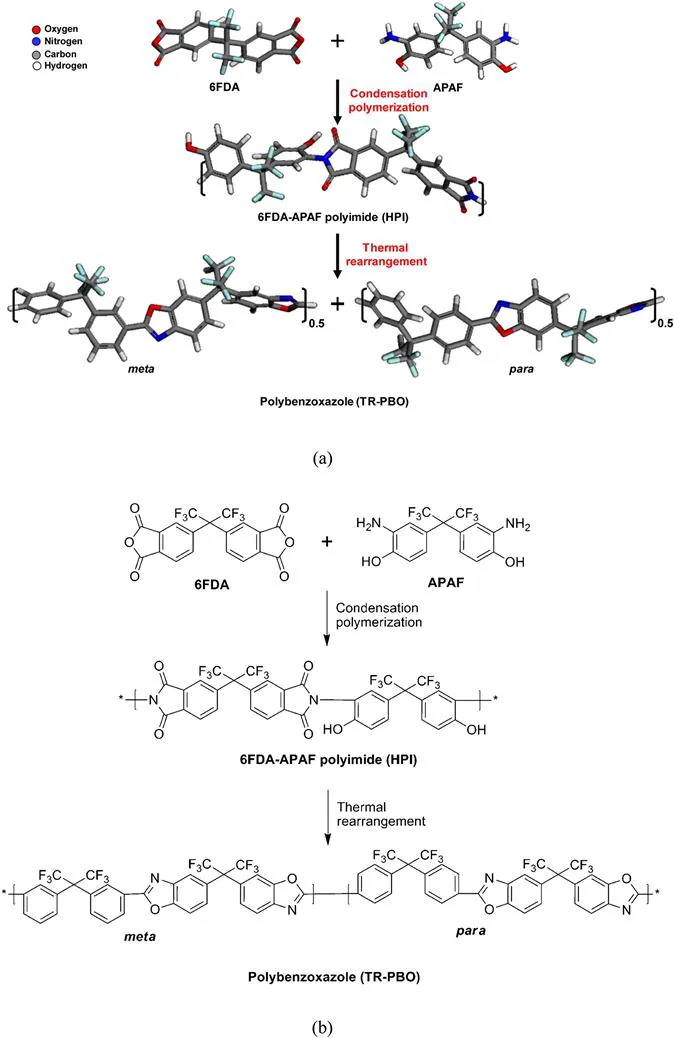

TR-polybenzoxazole (PBO) polymers are examples of novel membrane materials with high free volume elements and narrow cavity size distribution based on rigid microporous structures. TR-PBO polymers are glassy aromatic polymers with heterocyclic rings prepared by an in situ thermal treatment (350–450 °C) of hydroxyl-polyimide (HPI) precursors with functional groups at the ortho-positions. Since 2007, Lee’s group has been studying the thermal conversion mechanism of TR polymers for their application as membrane materials.16–24 A hydroxyl-polyimide is prepared by a conventional polycondensation reaction of dianhydrides and diamines with hydroxyl functional groups, obtaining a hydroxyl-containing poly(amic acid) (HPAAc) (Figure 1.1). Then, the HPAAc is converted to hydroxyl polyimide by various imidisation methods, such as thermal, chemical, and azeotropic imidisation, based on the dehydration of the poly(amic acid) structure. The final thermal rearrangement of the hydroxyl polyimide into TR-PBO is carried out at a temperature of 350–450 °C under an inert atmosphere after membrane formation.

Figure 1.1 (a) Atomistic model and (b) chemical structure of hydroxyl-containing polyimide (HPI) and thermally rearranged polybenzoxazole (TR-PBO). Reprinted with permission from Chi Hoon Park, Elena Tocci, Young Moo Lee, Enrico Drioli Thermal Treatment Effect on the Structure and Property Change between Hydroxy-Containing Polyimides (HPIs) and Thermally Rearranged Polybenzoxazole (TR-PBO) The Journal of Physical Chemistry B 2012, 116(42), pp 12864–12877. Copyright © 2012 American Chemical Society.

Another strategy used in the thermal process is the introduction of thermally labile molecules in a cross-linkable polyimide to prepare highly permeable polyimide membranes by thermal decomposition of the labile units in the solid state.26–28 Furthermore, TR copolymers have also been investigated in terms of the concerted effects of different TR polymers with several glassy polymers.29–34 These polymers show outstanding physical properties and high permeability, exceeding the limits of more conventional polymers due to their unusual microstructure, a phenomenon that has been explained as the result of the modifications in the polyimide chain during rearrangement into the solid state structure. Such a process leads to the formation of rigid rods with a concomitant conformation randomisation resulting from the formation of meta- and para-linked chains.16

Moreover, this causes an increase of the free volume distribution, which improves their general mass transport performance.16,24,29–37 In fact, during thermal rearrangement into the solid state, a microporous structure with interconnected microcavities is obtained with a distribution of narrow cavities accessible to small gas molecules.

However, it is still challenging to demonstrate how and to what extent the thermal treatment affects the polymer structure at the atomistic and molecular levels, specifically in terms of its configuration, conformation, glassy transition temperature, and/or free volume. In particular, if a chemical reaction occurs during the thermal treatment, the structure–property relationships of the starting and final structures become more and more complex.38,39

The physical properties of TR polymer membranes depend on the polymer backbone structure, as well as on the imidisation method.20 A great advantage of TR polymers lies in the possibility of determining their cavity size by designing appropriate polymer structures and thermal reaction mechanisms.16

1.1.2 Computational Approach to Polymeric Membranes: From Macro- to Atomistic Scale

The design and optimisation of polymeric membranes for gas separation by numerical simulation would be possible if reliable predictions of material and transport properties could be made significantly more rapidly than the corresponding syntheses and experiments. During the last decade, computational chemistry has had a favourable impact in almost all branches of materials research, ranging from phase determination to structural characterisation and property prediction,40–45 as it allows for dealing with different types of polymers as well as, for example, with polymer colloids such as cement slurries,46 the thermal conductivity of composites,47 and advanced batteries.48,49

New materials are often developed not so much based on rational considerations, but rather by trial-and-error decisional processes, in part due to the challenging time and length scales involved in modelling transpor...

Table of contents

- Cover

- Title

- Copyright

- Preface

- Contents

- Chapter 1 Modelling of Gas Separation in Thermally Rearranged Polymeric Membranes

- Chapter 2 Materials by Design: Multiscale Molecular Modelling for the Design of Nanostructured Membranes

- Chapter 3 Thermally Rearranged Polymers: The Ultimate Solution for Membrane Gas Separation

- Chapter 4 Analysis of Gas and Vapor Sorption in Polymer Membranes of Interest for Gas Separation (Including Ionic Liquids)

- Chapter 5 Highly Permeable Polymers for the Treatment of Gases (PIMs)

- Chapter 6 Graphene-based Membranes for Gas Separation

- Chapter 7 Mass Transport in Zeolite Membranes for Gas Treatment: A New Insight

- Chapter 8 Cost Competitive Membrane Processes for Carbon Capture

- Chapter 9 Polymeric Membrane-based Plants for Biogas Upgrading

- Chapter 10 Membrane Absorption