![]()

PART 1

Ecosystem Framework

![]()

Chapter 1

Introduction

In this chapter, we provide an overview of the supply chain networks, the recent developments due to globalization, and introduce the notion of supply chain ecosystem. For the last four decades the supply chains of various verticals are very well studied to optimize the supply-demand matching, lead time, and cost. Taking lessons from manufacturing, particularly from Japan, the supply chains have been designed to be of high performance. Globalization has restructured and stretched the supply chains across the national borders. They are highly connected logistically for flow of goods, through Internet for flow of information, and financially for flow of funds. Dense connectedness has made the supply chains fragile and highly risk prone. The financial crisis of 2007 in USA propagated into global trade crisis affecting the flow of goods across the globe.

Our thesis here is that the supply chain designs of yesteryears are inadequate and one has to think of redesign of supply chain networks taking into account the entire ecosystem. Ecosystem encompasses not just companies that make up the supply chain but also consists of their financial and informational partners, governments and regulators of the host countries, infrastructures that enable flow of goods, information, and finance.

1.1Supply Chain Networks

A supply chain network is a group of independent companies forming a strategic alliance with the common goal of designing, manufacturing, and delivering rightquality products to customer groups faster than other alliance groups and vertically integrated firms. A service chain network has a similar functionality for delivering service. Products generally have both supply and service chain networks. In a global supply or service network, the companies are geographically distributed. The dimension and complexity of the network vary depending on the vertical, the specific product, and its market. Both the supply and service chains are prevalent in automobile, pharmaceutical, aerospace, electronics, computer, food, apparel, etc. These networks are not generally under single ownership but are group formations of independent companies in alliance for a specific and special purpose. They compete with similar cooperating networks.

1.1.1Types of supply chains

We identify two types of supply chains based on the demographic and governance profiles.

Rural supply chains

The farm-to-fork food supply chain in emerging markets such as India starts with the farmers and ends with consumers buying from retail shops. The supply chain is fragmented and there is no single governing body. The supply chain is not designed but exists as a result of social culture, business practices, and regulations. There are too many intermediaries increasing the cost and unorganized business practices leading to wastage and inefficiencies. Rural supply chains are usually supply driven or push supply chains and hence are subject to high price volatility.

Industrial supply chains

Unlike rural supply chain, an industrial supply chain is created by forming strategic alliance among a group of independent companies with the common goal of designing, manufacturing, and delivering right-quality products to customer groups. We can identify two types of industrial supply chains: domestic and global. In a domestic or local supply chain, all the companies are co-located domestically catering to the local market. A global supply chain is internationally dispersed but with an integrated management strategy that blurs the national borders and treats all the constituent companies as part of the single supply chain network. Industrial supply chains have streamlined business-to-business and business-to-consumer processes supported with logistics, communication, and information technology infrastructure. Global supply chains in addition require international trade management to handle cross-border customs regulations and tax regimes.

Electronics, personal computing, apparel, and toys are verticals that usually have global supply chains. Texas Instruments’ high-speed telecommunications chip is conceived by engineers in Sweden, designed in Nice with software tools developed in Houston, produced in Japan and Dallas, and finally tested in Taiwan. Another classic example of disintegration of production is the popular Barbie doll. The plastic and hair are sourced from Taiwan and Japan, and the moulds and paints used for decorating the dolls are supplied from the US. The assembly is done in low-cost locations in Indonesia, Malaysia, and China.

It is important to realize that supply chains involve several stakeholders such as suppliers, contract manufacturers, logistics providers and financial institutions. The cost of the final product is made up of the costs of goods and services the product uses in its journey from suppliers to the customer. For example in the case of Barbie doll, the export value of a doll when it leaves Hong Kong for the US is $2. Out of $2, 35 cents is the value of Chinese labor, 65 cents for the cost of materials, and the rest goes for transport, overheads, and profits. The selling price of a doll is $10 in the US, of which Mattel, the lead manufacturer earns at least $1, and the rest covers transport, marketing, wholesale and retailing expenses in the US.

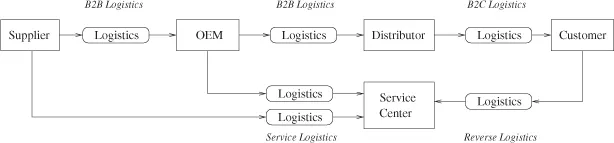

Fig. 1.1Integrated manufacturing and service network (Cradle-to-Cradle Protocol)

1.1.2The three flows in a supply chain

A well-designed supply chain network integrates three different flows: material flow, information flow, and financial flow. The logistics network provides a streamlined material flow between all partners, cutting down the lead time and cost of moving the raw materials, sub-assemblies, and finished goods to their destinations. Secure and reliable communications network, information technology, and IT-enabled services link all the companies of the enterprise, providing the information integration. The financial network connects financial institutions, insurance, credit rating agencies and all the other stakeholders enabling financial flow across the supply chain.

1.1.3The three sub-networks in a supply chain

Operationally, the integrated supply chain network has three sub-networks: demand network, supply network, and service network. The demand sub-network is the fulfillment arm of the supply chain consisting of the manufacturing, distribution, retailing and the associate logistical and finance functions. Timely delivery to the customer is a crucial function. The supply sub-network consists of the suppliers, manufacturers, inbound logistics, and the providers of the documentation needed for exports, imports, and funds transfer. This activity can be termed as primarily business-to-business. The service sub-network connects the end consumer with after-sales service centers, who are connected with the suppliers and manufacturers for spare parts procurement.

1.1.4The three business processes in a supply chain

The three primary business processes that constitute the functionalities in the supply chain are procurement, manufacturing, and distribution.

Procurement

The procurement function involves the acquisition of raw materials and components from the suppliers to produce the product. Procurement is broadly related to various activities such as vendor selection, material selection, outsourcing, negotiation, inventory management, inbound logistics, and to some extent, involvement in design. The supply sub-network is the primary procurer.

Manufacturing or assembly

Manufacturing is the set of production processes which use inputs from the suppliers to produce the products. The manufacturing function could be in a single location or geographically distributed.

Distribution and retail

Distribution consists of packaging and outbound logistics. Outbound logistics includes activities such as transportation planning, packaging, location analysis, and warehousing, as well as inventory management. Examples of typical logistics decisions include options such as direct shipping or hub-and-spoke, central warehouse or distributed network, intermodal or single mode, and third party services or private fleet. But, each of these issues includes tradeoffs among delivery time, responsiveness, quality and cost, as well as environmental performance.

1.1.5Supply chain governance

Governance models such as channel master, third party service providers and fourth party logistics providers exist today for supply-demand matching and in-store replenishment. However, supply chains are treated as simple linear processes of goods or services swiftly passing though an efficient logistics or IT pipeline and stakeholders concentrate only on that part of the pipe directly controlled by them or at best their customers and suppliers. The result is that there are three or four masters for the supply chain and each depends on the service-level agreements to keep supply chain smooth. However, uncertainty rules in the practical world. Consequentially, sales routinely deviate from forecasts; components are damaged in transit; production yields fail to meet plan; and shipments are held up in customs. In truth, schedule execution as per plans generated by supply chain planning is just a myth. Significant efforts are expended to expedite orders, to check order status at frequent intervals, to deploy inventory just-in-case and to add safety margins to lead times. Supply chain execution thus becomes a very important step. Currently, not much attention is being paid to this step. Monitoring the goods flow from origin to destination and making decisions to counter events that cause disruptions such as truck failures, customs payments or driver ill-health to maintain the commitments to the customers are functions of the execution team normally handled through call centers.

1.1.6Focus over the last two decades

In the early 1990s, companies were proud of their supply chains. Over the previous two decades, they had worked hard to reduce costs in all the three business processes — procurement, manufacturing, and distribution — using techniques such as the lean production, just-in-time manufacturing, single-source suppliers, and outsourcing. The biggest supply chain issue has been supply-demand matching, i.e. reducing obsolescent inventory, loss of sales, and improving customer satisfaction. Accordingly, academics and researchers have complemented with rich literature on supply chain management as an influential research topic in operations research and management science, focusing on problems related to planning and operations in supply-demand matching:

•Supplier/vendor selection; Order allocation;

•Facility location; Network design;

•Production planning; Hierarchical planning and scheduling;

•Inventory management; Pricing;

•Logistics and transportation.

The research on global supply chains continued to evolve in the predictable direction of including globalization-related issues to the above problems. Facility location and logistics considered costs related to international taxation, import and export duties, and constraints imposed by custom regulations. However, the evolution of global supply chains in physical realm has turned out to be more complex with unforeseen issues in addition to the supply-demand matching. This book focuses on these issues and proposes a unified framework for studying supply chains.

1.2Global Supply Chain Proliferation

Global supply chain networks have emerged as a tremendous source of value creation. The fortunes of companies still rise or fall based on their own earnings and stock performance, not the strength of their networks, although networks are playing an increasing role in their performance. Investors still buy stock in companies, but the extraordinary valuation of a company such as Google depends in large part on the network in which it is embedded. Companies such as eBay, Google, Facebook, Li & Fung, have become major players based primarily on the power of their networks. Established corporations such as Procter & Gamble and Toyota are harnessing networks to tap into new sources of innovation around the globe. The modern equivalent of Smiths pin factory is Li & Fung in Hong Kong. The company produces products for some of the world’s leading brands without owning any manufacturing plants but orchestrating a network of 7,500 partner organizations in 37 countries. Its competencies are not in manufacturing but in designing and managing the overall supply chain network.

The migration of sourcing, manufacturing, R&D, and service operations from high cost countries to low cost countries has accelerated. There is an upsurge of outsourcing to India and China. Availability of excellent infrastructure, skilled and educated manpower at low wages enable companies in these countries to deliver high quality products on time. Most countries where businesses are migrating have made investments in infrastructure and also adopted favorable economic policies. Supply chain networks with suppliers located in North America, Europe, and China; customers in the U.S., Europe, and Japan; factories in Asia Pacific, Brazil, Europe, and North America; and development engineers in Europe, India, and North America are common now. A product, either physical or digital, that is made entirely in any one country by any one company is a rarity now.

Globalization is, however, acting as two-edged swords for many business organizations. On one hand, the global networks enable companies with attractive vistas of wide new sourcing horizons i.e. to be able to source from the very best suppliers and fresh market opportunities i.e. to sell into every potential market. On the other hand, companies are exposed to challenges and disturbances globally.

1.2.1Institutional innovations and threats

In 2010, the Canadian company Research in Motion (RIM) found its Blackberry in trouble over new security requirements by governments in the Middle East and in India. The Middle Eastern and Indian governments have lately realized that the tight security provided by Blackberry is taken advantage of by various anti-social elements for subversion. RIM was asked to drastically change the security functionalities of Blackberry, on the threat of being banned. Blackberry being a global product, RIM has to take into account every requirement or change that comes its way from anywhere in the globe.

Institutional threats can also be non-governmental and equally a menace to domestic supply chains. The Tata’s ambitious Nano car project in India was launched in Singur, but was later withdrawn with a huge loss due to pressure from the farmers who felt victimized by the acquisition of land over whi...