![]()

Part 1

Strategic Issues and Supply Chain

Design

Chapter 1

Supply Chain Management and Strategy

Chapter 2

The Right Design of a Supply Chain

![]()

Chapter 1

Supply Chain Management and Strategy

1.1Understanding the Supply Chain and Supply Chain Management

Supply chain management is a relatively new field of management study in comparison with the traditional business fields such as marketing, finance, and production management. The newness of the field results from the concept of using an integrated management for order fulfilling activities. In the early 1960s, MIT professor Jay Forrester studied the interrelationship between suppliers and customers and uncovered the phenomenon that inventories in a supply pipeline tend to fluctuate more as they are further away from the customer. This phenomenon leads either to unfilled orders or to too much in inventory. In the early 1980s, Harvard professor Michael Porter suggested that companies could be more competitive if they were better able to manage the interrelationship of their inbound logistics, outbound logistics, operations, sales and marketing, and customer services. Porter used the term “value chain” to discuss the process upon which the current supply chain framework is built.

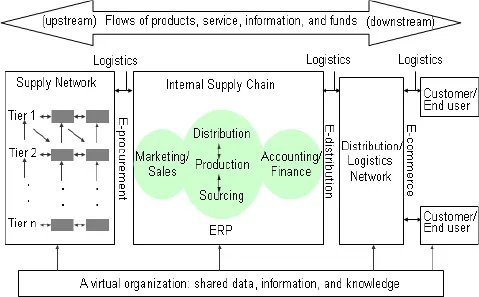

The current version of the Supply Chain encompasses all of the activities in fulfilling customer demands and requests, as shown in Fig. 1.1. These activities are related to the flow and transformation of goods from the raw materials stage to the end user, as well as the associated flows for information, service, and funds. There are four stages in a supply chain: the supply network, the internal supply chain (the manufacturing plants), the distribution systems, and the end users. Moving up and down the stages are the four flows: the material flow, the service flow, the information flow, and the funds flow. The interrelationship in a supply chain is connected by business activities. For example, the procurement links the supply network and manufacturing plant, distribution links the manufacturing plant and the distribution network, and commerce or e-commerce links the distribution network and the end users (see Fig. 1.1).

Fig. 1.1 Supply chain in an e-business environment.

Let us consider the case of the purchase of a Dell computer. The supply chain begins with the need for a computer. In this example, a customer places an order for a Dell computer through the Internet. Since Dell does not have distribution centers or distributors, this order triggers the production of that computer at Dell’s manufacturing center, which is the next stage in the supply chain. Microprocessors used in Dell’s computer may come from Advance Micro Devices (AMD); a complementary product like a monitor may come from Sony. Dell receives such parts and components from these suppliers, who belong to the upstream stage of the supply chain. After completing the order according to the customer’s specification, Dell then sends the computer directly to the user through UPS, a third party logistics provider. This responsive supply chain is illustrated in Fig. 1.1. In this order fulfillment process, Dell Computer is the captain of the supply chain; it selects the suppliers, forges partnerships with other members of the supply chain, fulfills orders from customers, and follows up the business transaction with services.

Now, consider a case of purchasing a pack of Perdue Farms chicken breasts at Sam’s Club, a warehouse wholesale club. When customers buy trays of chicken breasts at Sam’s Club, the demand is satisfied from inventory that is stocked in a Sam’s Club distribution center. Production at a Perdue Farms manufacturing facility is based on forecast demand, using historical sales data. Perdue Farms runs a vertical supply chain that begins with the eggs, continues to the grains that feed chicks, and is followed by manufacturing, packaging, and delivery. 1This is an efficient supply chain and is illustrated in Fig. 1.1.

These two different types of supply chain, responsive supply chain and efficient supply chain, will be discussed in detail in section 1.6.2.

Supply Chain Management is a set of synchronized decisions and activities utilized to efficiently integrate suppliers, manufacturers, warehouses, transporters, retailers, and customers so that the right product or service will be distributed at the right quantities, to the right locations, at the right prices, in the right condition, with the right information, and at the right time, in order to minimize system-wide costs while satisfying customer service requirements. The objective of Supply Chain Management (SCM) is to achieve a sustainable competitive advantage.

A company’s supply chain in an e-Biz environment can be very complicated. Fig. 1.1 illustrates a simplified supply chain because many companies have hundreds and thousands of suppliers and customers. The supply chain in Fig. 1.1 includes internal supply chain functions, an upstream supply network, and a downstream distribution network. The logistics function facilitates the physical flow of material from the raw material producer to the manufacturer, and then to the distributor, and finally to the end user.

The internal supply chain of the focal manufacturing company in the middle of Fig. 1.1 includes sourcing, production, and distribution. Sourcing, or the procurement function of a company, is responsible for selecting suppliers, negotiating contracts, formulating the purchasing process, and processing orders. The Production function is responsible for transforming raw materials, parts, or components into the product. The Distribution function is responsible for managing the flow of material and the finished goods inventory from the manufacturer to the customer. Enterprise Information Systems (ERP) integrate the entire company’s information system, process and store data, and link functional areas, business units, and product lines in order to assist managers in making business decisions. As an IT infrastructure, ERP influences the way in which companies manage their daily operations and facilitates the flow of information among all of the supply chain processes of a firm.

The supply network on the left-hand side of Fig. 1.1 consists of all the organizations that provide materials or services, either directly or indirectly. For example, a computer manufacturer’s supply network includes all of the firms that provide its needed items (ranging from such raw materials as plastics and computer chips, to subassemblies like hard drives and motherboards). A supplier of motherboard, for instance, may have its own set of suppliers (second-tier suppliers) that provide inputs and that are also part of the supply chain.

The distribution network on the right-hand side of Fig. 1.1 is responsible for the actual movement of materials between locations. Distribution management involves the management of the packaging, storing, and handling of materials at receiving docks, warehouses, and retail outlets. A major part of distribution management is transportation management, which includes the selection and the management of external carriers or internal private fleets of carriers.

Commerce or E-commerce uses advanced technology to assist business transactions in a web-based environment and facilitates the transaction of information flow and fund flow. E-commerce involves business-to-business (B2B) transactions such as Covisint.com (an on-line industrial collaboration platform), business-to-customer transactions such as Amazon.com (B2C), customer-to-business (C2B) transactions such as Priceline.com, and customer-to-customer (C2C) transactions such as eBay auctions. E-commerce is conducted through a variety of electronic media. These electronic media include the Internet of Things (IoT), electronic data interchange (EDI), electronic funds transfer (EFT), radio frequency identification (RFID), bar codes, fax, automated voice mail, CD-ROM catalogs, and a variety of others.

Distribution instructs where to locate the sources of supply and advises how to access them, as well as how to move the materials to the retailers or to the end user via the Internet or a web-based environment.

Procurement is a function that acquires material needed for manufacturing the goods. E-procurement completely revolutionizes a manufacturing or distribution firm’s supply chain, creating a seamless flow of order fulfillment information from manufacturer to supplier.

Now that we have characterized the nature of supply chain management, we are ready to make a few relevant points:

1.The objective of supply chain management is to be efficient and cost-effective through collaborative efforts across the entire system.

2.The role of supply chain management is to produce products that conform to customer requirements.

3.The scope of supply chain management encompasses the firm’s activities from the strategic level through the tactical and operational levels, since it takes into account the efficient integration of suppliers, manufacturers, wholesalers, logistics providers, retailers, and end users.

1.2Virtual Integration in the Supply Chain

There are two important technological innovations that have made supply chain virtual integration possible: the advent of advanced information technology and container boxes. The former shortened the geographic distance by providing a virtual information highway and the latter has lowered the cost of transportation which has helped to justify shipping a large volume of goods from the eastern hemisphere to the western hemisphere. Between the two innovations, information technology and container boxes, information technology plays the more important role in extending the supply chain beyond a firm’s business boundary to involve global business and trading partners. Virtual integration is discussed in this section, and containerization will be discussed in the next section.

Virtual integration is using information technology and information to blur the traditional boundaries among the suppliers, manufacturers, distributors, logistics providers, and end users in a supply chain. Today, the virtual cooperation between various firms in a supply chain is apparent through suppliers’ and customers’ ability to trade over the Internet in real-time in order to create maximum value. Virtual integration offers the advantage of a tightly coordinated supply chain that has traditionally come through vertical integration. In the age of virtual organizations, managers, engineers, professional staff, and technical workers are no longer the lone custodians of the corporate knowledge base. Knowledge is shared across cultural boundaries, time boundaries, and space boundaries in order to create strategic frontiers in global and virtual enterprises.

The seamless virtual integration of the firms within a supply chain requires real-time automation of the inter-organizational business processes that span across trading partners. Today, Enterprise Information Systems are a state of the art technology that enables supply chain partners to integrate and coordinate their supply chain processes. Within an organization, ERP systems create a central data structure which ensures that information can be shared across all of functional levels in real time.

The traditional arm’s length transaction from one stage of a supply chain to the next is illustrated in Fig. 1.2(a).2 In this view, organizations view their suppliers and customers as adversaries who are not to be trusted. This prevents their entry into successful long-term relationships. Performance is often narrowly viewed, and procurement decisions are often based solely on price. Business relationships are viewed in terms of a zero-sum game in which there is a clear winner and me in which there is a clea d a clear lose er.

The integrated supply chain model that Dell Inc. has created is illustrated in Fig. 1.2 (b). This model focuses on the mutual trust and respect of supply chain membbers, utilizes a just-in-time manufacturing strategy, and eliminates third-party retailers. With this integrated supply chain, Dell only holds five days of invenntory, and has a build cycle of two days (on most systems). The integratted supply chain includes joint improvement projects, training seminars, workshopps, and meetings between the organizations’ top management members. As the degr...