![]()

Chapter 1

Mechanics Engineering

![]()

Research of the stress-strain relationships of metal thin-walled tube

Yu-Han Li and Jian-Wei Liu*

Department of Experiential Practice,

Guilin University of Electronic Technology,

Guilin, Guangxi, China*E-mail: [email protected] 1. Introduction

Lightweight structure[1] is one of the development trends of advanced manufacturing technology at present. The metal thin-walled tubes are realized with lightweight structure, because they can be replaced by solid structures with hollow structures under the premise of ensuring the strength. Nowadays, they have been widely used in automotive and aircraft industries, household appliances and other components. In the forming process of thin-walled tube, the tubular plastic stress-strain relationships not only have important implications for the whole forming process [2], but also are the precondition of the finite element simulation technique for metal materials processing [3].

In this paper, the development of the methods for determining the stress-strain relationships of tubular materials is introduced,and the methods for establishing stress-strain relationships based on hydraulic bulge test are described detailedly. Finally, some typical approaches for verifying the stress-strain relationships are presented. This paper has a guiding significance for building the stress-strain relationships in Tube Hydro-forming (THF) technology.

2. Establishing the Stress-Strain Relationships of Tubular Materials Based on Tensile Test

Li Bo et al.[4] intercepted the parent metal and weld specimen from the SS304 stainless steel tailor-welded tube, and determined plastic hardening parameters under uniaxial tensile test. A mixed material specimen was intercepted from the Q215 stainless steel tailor-welded tube and tensile tests were carried out by Mei Zhan [5] et al., the results show that tensile specimens of sufficient width to include the weld bead, heat affected zone, and parent metal are suitable considering the constraint among the weld bead and parent metal.

However, the tensile test of flat or circular specimen can only reflect the mechanical properties of a certain direction of the tube, and can not get the comprehensive performance of the tube. In order to measure the comprehensive mechanical properties of the pipe more accurately, it is required that the tubes be tested in the biaxial stress state. Thus hydraulic tube bulge test is mostly preferable and recommended.

3. Building the Stress-Strain Relationships of Tubular Materials Based on Hydro-Forming Test

To build reliable and accurate flow stress of thin-walled tubes, hydraulic bulging method based on the real stress state is one of the most reasonable approaches. But the equivalent stress and equivalent strain of tube stress-strain relationship must acquired two important parameters based on curvature of deforming tube[6], namely the meridian radius ρφ and circumferential radius ρz.

3.1. Assuming method

Based on the plastic membrane theory and the incremental theory, Bortot P et al.[7] measured multiple tubes and established the flow stress equation of a thin-walled tube. Measurement method was complicated because the meridian radius ρφ is directly measured in the test, and the test equipment cost is high. Boudeau N et al.[8] assumed that the bulging contour is the circular arc, and calculated ρφ using geometrical relationship, then determined the stress-strain relationships based on related plastic forming theory.

The direct measurement of the radius of the meridian curvature can be avoided by the assumption that the bulging profile curve in advance. It has greatly improved the efficiency of testing, but the error of the actual bulging contour is relatively large, and the accuracy of the stress-strain relationships is reduced.

3.2. Off-line measuring method

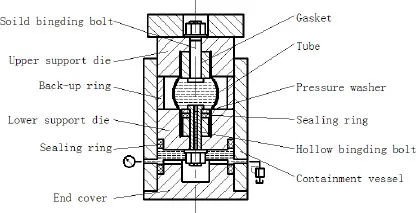

Based on the plastic membrane theory and static equilibrium equations, a hydro bulging approach is proposed by Yang LF et al.[9]with curve-fitting of the experimental data to establish the flow stress equation of a thin-walled tube in THF process, where the site measurements of stress and strain distribution. The hydro-bulging test tooling is shown in Fig. 1.

The method obtained bulging date by off-line measuring, constructed the equation of bulging generatrix, and the bulging shape of the pipe is made credibly. It had good application value, but its measurement task was complicated, and its measuring accuracy directly affected the solution of the axial curvature radius.

3.3. On-line measuring method

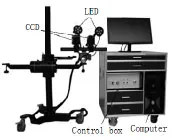

A unique on-line measurement approach based on digital speckle correlation method is put forward by Liu Jian-wei et al.[6] to determine flow stress of thin-walled tube in THF process. The bulging experiment device and measuring device is shown in Fig. 2 and Fig. 3.

M. Saboori et al.[10] has carried out ...