- 520 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

Fundamentals of Tribology

About This Book

Fundamentals of Tribology deals with the fundamentals of lubrication, friction and wear, as well as mechanics of contacting surfaces and their topography. It begins by introducing the reader to the importance of tribology in everyday life and offers a brief history of the subject. It then describes the nature of rough surfaces and the mechanics of contacting elastic solids and their deformation under load and friction in their relative motion. The book goes on to discuss the importance of lubricant rheology with respect to viscosity and density. Then, the principles of hydrodynamic lubrication are covered with derivations of the governing Reynolds and energy equations. Applications of hydrodynamic lubrication in various forms of bearings — journal bearings, thrust bearings and externally pressurised bearings — are outlined. The important and still evolving subject of elastohydrodynamic lubrication is treated in some detail, both at its fundamentals and its applications in thin shell or overlay bearings, cam-followers and internal combustion engine pistons.

The fundamentals of biotribology are also covered, particularly its applications to endo-articular mammalian joints such as hip and knee joints and their arthroplasty. In addition, there is a treatment of the rapidly emerging knowledge of tribological phenomena in lightly loaded vanishing conjunctions (nanotribology), in natural systems and very small devices, such as MEMS and high density data storage media. There is also a new chapter on the rapidly emerging subject of surface texturing to promote retention of microreservoirs of lubricant, acting as microbearings and improving lubrication of otherwise poorly lubricated conjunctions.

This book targets the undergraduate and postgraduate body as well as engineering professionals in industry, where often a quick solution or understanding of certain tribological fundamentals is sought. The book can also form an initial basis for those interested in research into certain aspects of tribology.

Contents:

- Introduction to Tribology

- The Nature of Rough Surfaces

- Elastic Solids in Normal Contact

- Dry Friction and Wear

- Lubricant Properties

- The Reynolds and Energy Equations

- Thrust Bearings

- Journal Bearings

- Externally Pressurised (EP) Bearings

- Elastohydrodynamic Lubrication (EHL)

- Fatigue Life of Rolling Element Bearings

- Transient Elastohydrodynamic Lubrication

- Nanotribology

- Biotribology

- Surface Texturing for Enhanced Tribological Performance

Readership: Students in an undergraduate course in Mechanical, Chemical or Automotive Engineering or Material Science in later years of their courses. Postgraduate students on taught course within the same disciplines. Early career researchers (working towards a PhD degree or as Research Associates) as well as researchers in an R&D environment in industry.

Tribology;Lubrication;Wear;Friction;Biotribology;Nanotribology;Hydrodynamics;Elastohydrodynamics;Bearings0 Key Features:

- The book provides a broad scope in the field of tribology across the physical scale from nano-scale to micro-scale and onto system level investigations. It covers a broad range of traditional applications, such as bearings to modern research-led issues including MEMS and storage devices. It also includes biotribology and the new growing field of laser surface texturing. The breadth of applications as well as the multi-scale approach is rather unique within the books of tribology currently on the market

- The approach is also multi-disciplinary in terms of underlying physics, including the interactions between system dynamics, tribology and thermal analysis as well as aspects of physical chemistry and biomechanics

Frequently asked questions

Information

Chapter 1

Introduction to Tribology

1.1Introduction

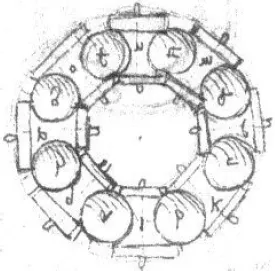

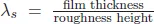

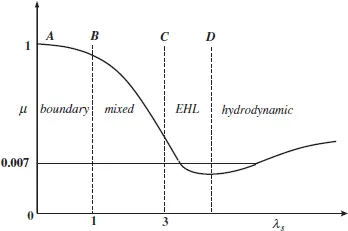

1.2Regimes of lubrication

Table of contents

- Cover

- HalfTitle

- Notable Titles of Interest

- Title

- Copyright

- Preface

- Acknowledgements

- Notation

- Contents

- Chapter 1. Introduction to Tribology

- Chapter 2. The Nature of Rough Surfaces

- Chapter 3. Elastic Solids in Normal Contact

- Chapter 4. Dry Friction and Wear

- Chapter 5. Lubricant Properties

- Chapter 6. The Reynolds and Energy Equations

- Chapter 7. Thrust Bearings

- Chapter 8. Journal Bearings

- Chapter 9. Externally Pressurised (EP) Bearings

- Chapter 10. Elastohydrodynamic Lubrication (EHL)

- Chapter 11. Fatigue Life of Rolling Element Bearings

- Chapter 12. Transient Elastohydrodynamic Lubrication

- Chapter 13. Nanotribology

- Chapter 14. Biotribology

- Chapter 15. Surface Texturing for Enhanced Tribological Performance

- Questions

- Book of Solutions

- Index