![]()

1 Introduction

Abstract

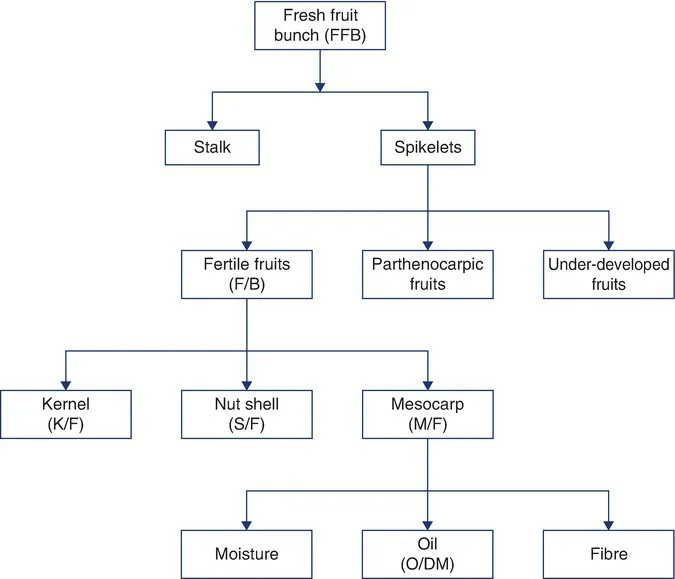

A brief history of bunch analysis of the oil palm crop is provided. This includes bunch components (stalk, spikelets, fruits, mesocarp, nuts, shell and kernels) and oil yield analysis. These parameters are used by oil palm breeders to analyse the oil yield potentials (e.g. quantity and quality comparison of bunches, between bunches within an oil palm, between oil palms or between different progenies). Obtaining high fresh fruit bunch (FFB) production in oil palm plantations per hectare area per year, and high oil extraction rates from the bunch, are the main goals of growers to produce maximal oil yield. Oil extraction rates determined in the laboratory are useful in this respect, in monitoring and verifying extraction rates in oil mills.

1.1 Oil Palm Production Facts and Figures

Oil palm has the Latin name Elaeis guineensis Jacq; the genus name is derived from the Greek elaion, meaning ‘oil’, and the species name indicates its origin in West Africa. The crop was discovered by travellers to Africa in the 15th century, but the first plantings in Indonesia, which led to its rise as the world’s pre-eminent oil crop, did not occur until the late 19th century. Large scale plantations were established in the early 20th century in both Africa and South East Asia as interest in the crop developed. The first plantations were composed of Dura palms which have thick-shelled fruits (Fig. 1.1). In the 1920s the first crosses were made in deliberate attempts to improve the crop through plant breeding, and in the 1950s–60s the more productive Tenera types (a result of crossing Dura with Pisifera) took over as the favoured commercial material both in Africa and South East Asia. Tenera genotypes are thin-shelled and have thick oil-bearing fruit flesh (mesocarp) with a 30% greater oil yield compared to Duras. Oil is also obtained from the kernel.

A comprehensive review of the oil palm crop is given by Corley and Tinker (2015). Oil palm is grown in the humid tropics between 20° latitudes north and south of the equator and covers over 8.5 million hectares worldwide. The crop is highly profitable and grown both on large scale plantations and by smallholders (Sayer et al., 2012). It should be noted that of all the oil producing crops exploited at present, oil palm is by far the most efficient on an oil volume per hectare basis.

1.2 Palm Oil Fruit Morphology and Oil Composition

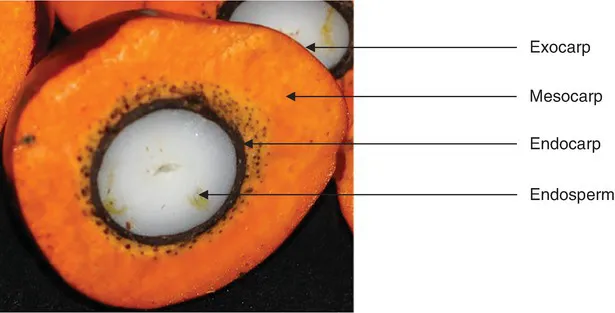

The oil palm fruit consists of an outer pericarp, an outer skin (exocarp), an oily flesh (mesocarp) and a shell (endocarp). The pericarp organs are maternal and derived from the carpel of the mother palm. The kernel is composed mainly of endosperm that supports the growth of the enclosed embryo. The endosperm and embryo are products of fertilization. Crude palm oil (CPO) is extracted from the outer mesocarp and crude palm kernel oil (CPKO) is extracted from the endosperm.

The mesocarp of oil palm fruits is made up of the three major components: oil, water and fibre. Oil palm fruits provide both CPO and palm kernel oil (PKO), extracted from the fruit flesh (mesocarp) and kernel (endosperm), respectively (Fig 1.2). Oil palm is by far the highest oil yielding crop, averaging 3–4 tonnes of mesocarp oil per hectare per year in the major palm oil producing countries (Wahid et al., 2005). Fatty acids in CPO consist of palmitic acid (44%), oleic acid (39%), linoleic acid (11%), stearic acid (5%) and other fatty acids (Siew, 2002), and CPO is a major source of pro-vitamin A and vitamin E (Barcelos et al., 2015). Vitamin E content in CPO ranges between 600 ppm and 1,000 ppm (Choo et al., 1995). Carotene and sterols are minor components of CPO (Tenera) and the average carotene content in Deli Dura is about 500 ppm (Corley and Tinker, 2015). The Malaysian standard for carotene content in CPO is 474–689 ppm (Malaysian Standard MS 814, 2007). PKO is a high quality oil containing lauric acid (up to 50%), myristic acid (17%), palmitic acid (8%), oleic acid (13%) and other essential fatty acids (Siew, 2001).

The shell thickness characteristic (see Fig. 1.1) of Dura is thick-shelled: the shell is 2–8 mm thick, occasionally less, 35–65% mesocarp/fruit, no fibre ring surrounding the nut in cross-section; Tenera fruits are thin-shelled: shell 0.5–4 mm, 55–96% mesocarp/fruit and a fibre ring is present; Pisifera are shell-less and usually female sterile (Corley and Tinker, 2015).

Recent comparative studies of the characteristics of FFB yield of palm oil and palm kernel oil of Dura, Pisifera and Tenera genotypes in North Sumatra, Indonesia (Basyuni et al., 2017) show:

• Oil percentages of mesocarp: 56% in Tenera, 49% in Dura and 61% in Pisifera fruits.

• CPO percentages: 24% in Tenera, 23% in Dura and 26% in Pisifera fruits.

1.3 Palm Oil Production

Harvesting should allow the collection of all ripe bunches in a plantation without damaging the fruit (or the palm) to obtain optimal oil content and oil quality. Methods of harvesting are usually written down in standard operating procedures (SOPs). The SOPs of harvesting should cover the specific interval time between rounds of harvesting a block of palm trees in a plantation as well as observation notes. The maximum time interval is about 10 days, which should prevent any bunch becoming over-ripe. A study comparing harvesting intervals from 10 to 15 days was carried out by Mohanaraj and Donough (2016) and showed 10 days to be the best harvest interval. Harvesting observations should be made on developing fruit bunches – e.g. fruit colour changes (black to red for nigrescens genotypes; green to orange for virescens genotypes), number of loose fruits (detached fruits on the ground) before and after harvesting, fruit ripeness, etc.

Fruit colour helps the harvester to identify the maturity stage of fruit bunches (either nigrescens or virescens type – see Fig. 1.3). Over-ripe fruit will have bright orange and yellow colours in nigrescens and virescens types respectively. Ripe fruits will have a yellow/orange or red/orange colour; under-ripe fruits will have a reddish black colour or green colour; and unripe fruits will have a mostly black or green colour in nigrescens and virescens fruit respectively. The number of loose fruits (fruits found on the ground) before harvesting is normally 1–5 or 5–10 fruits, depending on the estate SOPs (this corresponds to the ripeness and quality of the fruit bunch). Under-ripe and unripe bunches will diminish the oil quality due to higher free fatty acids and lower oil yield. Also, over-ripe fruit bunches will lose oil during field handling and transportation to the mill. In some cases, the harvesting SOPs also count the number of loose fruits after harvesting (less than five loose fruit/kg bunch weight), minimum weight of bunch (minimum weight is normally 3 kg) and stalk length (less than 2 cm). Ripe fruits have optimum oil extraction rates and good quality. Woittiez et al. (2016) list the following characteristics for ripe fruits:

• Yellow/orange/red colour for nigrescens types.

• Yellow/orange coloured fruits for virescens types.

• Good bunch appearance (no pests or diseases).

• High fertility (bunch is full of fruits).

• Fruits are soft and oil drips out when fruit is cut.

Ripe fruit bunches are harvested continually and sent to local mills for oil extraction and high scale production of CPO and CPKO (Fig. 1.4). The main CPO producing countries are Indonesia and Malaysia, which supply 55% and 30% of the total global production, respectively. These two countries produce 63.82 million tonnes (MnT) per year; Indonesia provides 54 and Malaysia 36% of total CPO exports worldwide, equivalent to 46.74 MnT. The largest importers are India (20%), followed by Europe (16%) and China (11%), with a total import equal to 46.71 MnT (Oil World, 2017).

Most palm oil is used in the food industry and is a major source of lipids (Wahid et al., 2005). Palm oil is used mainly for edible purposes, whereas palm kernel oil has wide applications in the oleochemical industry (Sambanthamurthi et al., 2000). The downstream oleochemical industry produces a ...