- English

- ePUB (mobile friendly)

- Available on iOS & Android

Engineering Principles in Biotechnology

About this book

This book is a short introduction to the engineering principles of harnessing the vast potential of microorganisms, and animal and plant cells in making biochemical products. It was written for scientists who have no background in engineering, and for engineers with minimal background in biology. The overall subject dealt with is process. But the coverage goes beyond the process of biomanufacturing in the bioreactor, and extends to the factory of cell's biosynthetic machinery.

Starting with an overview of biotechnology and organism, engineers are eased into biochemical reactions and life scientists are exposed to the technology of production using cells. Subsequent chapters allow engineers to be acquainted with biochemical pathways, while life scientist learn about stoichiometric and kinetic principles of reactions and cell growth. This leads to the coverage of reactors, oxygen transfer and scale up. Following three chapters on biomanufacturing of current and future importance, i.e. cell culture, stem cells and synthetic biology, the topic switches to product purification, first with a conceptual coverage of operations used in bioseparation, and then a more detailed analysis to provide a conceptual understanding of chromatography, the modern workhorse of bioseparation.

Drawing on principles from engineering and life sciences, this book is for practitioners in biotechnology and bioengineering. The author has used the book for a course for advanced students in both engineering and life sciences. To this end, problems are provided at the end of each chapter.

Tools to learn more effectively

Saving Books

Keyword Search

Annotating Text

Listen to it instead

Information

Chapter 1

An Overview of Bioprocess Technology and Biochemical Engineering

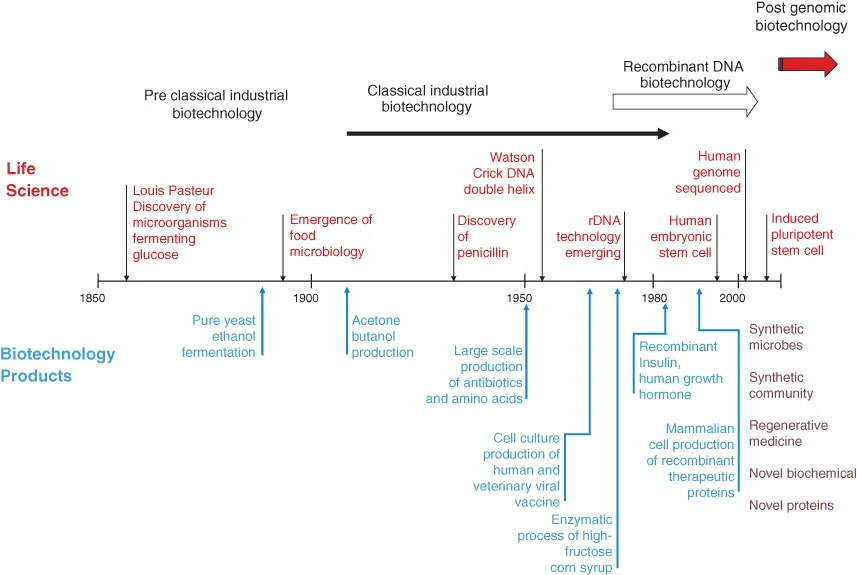

1.1 A Brief History of Biotechnology and Biochemical Engineering

1.1.1 Classical Biotechnology

Table of contents

- Cover

- Title Page

- Copyright

- Dedication

- Table of Contents

- Preface

- About the Companion Website

- Chapter 1: An Overview of Bioprocess Technology and Biochemical Engineering

- Chapter 2: An Introduction to Industrial Microbiology and Cell Biotechnology

- Chapter 3: Stoichiometry of Biochemical Reactions and Cell Growth

- Chapter 4: Kinetics of Biochemical Reactions

- Chapter 5: Kinetics of Cell Growth Processes

- Chapter 6: Kinetics of Continuous Culture

- Chapter 7: Bioreactor Kinetics

- Chapter 8: Oxygen Transfer in Bioreactors

- Chapter 9: Scale-Up of Bioreactors and Bioprocesses

- Chapter 10: Cell Culture Bioprocesses and Biomanufacturing

- Chapter 11: Introduction to Stem Cell Bioprocesses

- Chapter 12: Synthetic Biotechnology: From Metabolic Engineering to Synthetic Microbes

- Chapter 13: Process Engineering of Bioproduct Recovery

- Chapter 14: Chromatographic Operations in Bioseparation

- Index

- End User License Agreement

Frequently asked questions

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app