Beckett's Industrial Chocolate Manufacture and Use

- English

- ePUB (mobile friendly)

- Available on iOS & Android

Beckett's Industrial Chocolate Manufacture and Use

About This Book

Since the publication of the first edition of Industrial Chocolate Manufacture and Use in 1988, it has become the leading technical book for the industry.

From the beginning it was recognised that the complexity of the chocolate industry means that no single person can be an expert in every aspect of it. For example, the academic view of a process such as crystallisation can be very different from that of a tempering machine operator, so some topics have more than one chapter to take this into account. It is also known that the biggest selling chocolate, in say the USA, tastes very different from that in the UK, so the authors in the book were chosen from a wide variety of countries making the book truly international. Each new edition is a mixture of updates, rewrites and new topics. In this book the new subjects include artisan or craft scale production, compound chocolates and sensory.

This book is an essential purchase for all those involved in the manufacture, use and sale of chocolate containing products, especially for confectionery and chocolate scientists, engineers and technologists working both in industry and academia.

The new edition also boasts two new co-editors, Mark Fowler and Greg Ziegler, both of whom have contributed chapters to previous editions of the book. Mark Fowler has had a long career at Nestle UK, working in Cocoa and Chocolate research and development – he is retiring in 2013. Greg Ziegler is a professor in the food science department at Penn State University in the USA.

Frequently asked questions

Information

CHAPTER 1

Traditional chocolate making

1.1 History

| Date | Event |

| 1519 | Cortez discovered that cocoa had been cultivated by the Aztecs more than 3000 years |

| 1528 | Cortez introduced a chocolate drink to Spain |

| 1606 | Chocolate drinking spread to Italy |

| 1615 | Chocolate drinking reached France |

| 1657 | First chocolate house established in London |

| 1727 | Nicholas Sanders invented a milk chocolate drink |

| 1746 | First cocoa planting in Bahia |

| 1765 | First chocolate company established in North America |

| 1828 | Van Houten patented the cocoa press |

| 1847 | Fry’s factory established in Bristol to produce eating chocolate |

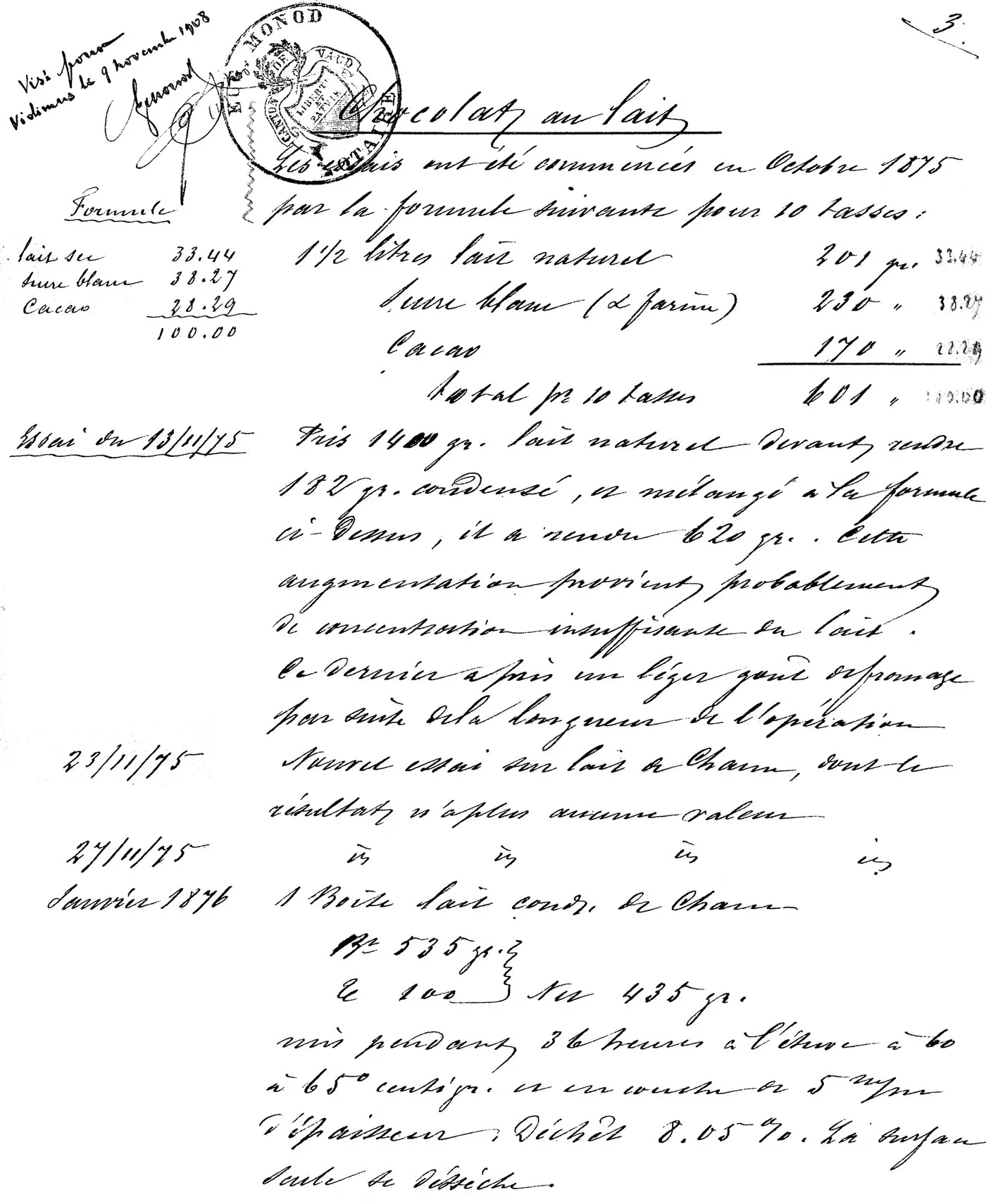

| 1875 | Daniel Peters manufactured milk chocolate |

| 1988 | World cocoa grindings exceeded two million tonnes |

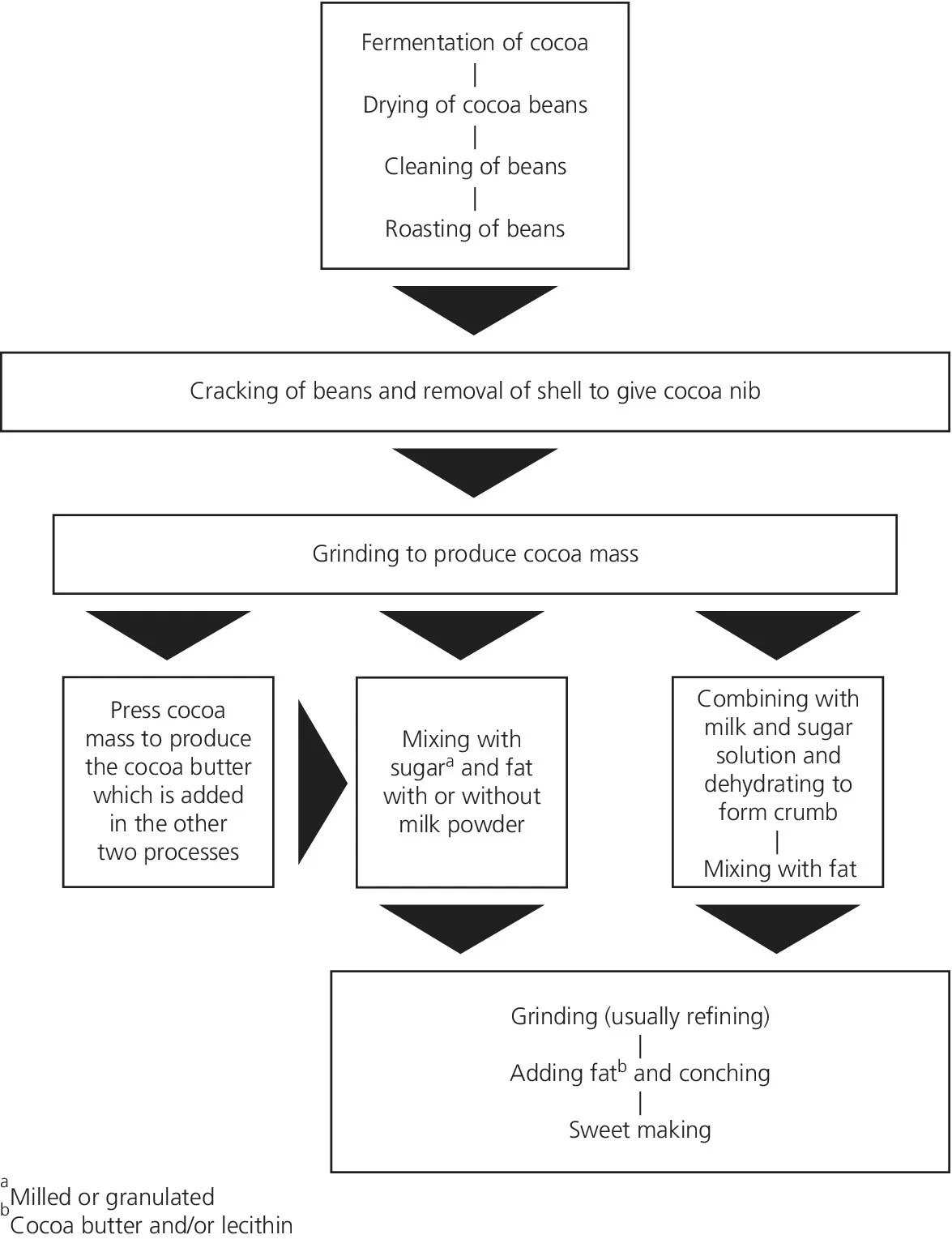

1.2 Outline of the process

1.2.1 Preparation of cocoa nib – flavour development

Table of contents

- Cover

- Title Page

- Table of Contents

- Contributors

- Preface

- CHAPTER 1: Traditional chocolate making

- CHAPTER 2: Cocoa beans

- CHAPTER 3: Production of cocoa mass, cocoa butter and cocoa powder

- CHAPTER 4: Sugar and bulk sweeteners

- CHAPTER 5: Ingredients from milk

- CHAPTER 6: Chocolate crumb

- CHAPTER 7: Properties of cocoa butter and vegetable fats

- CHAPTER 8: Flavour development in cocoa and chocolate

- CHAPTER 9: Particle size reduction

- CHAPTER 10: Conching

- CHAPTER 11: Chocolate flow properties

- CHAPTER 12: Bulk chocolate handling

- CHAPTER 13: Tempering

- CHAPTER 14: Moulding, enrobing and cooling chocolate products

- CHAPTER 15: Non‐conventional machines and processes

- CHAPTER 16: Chocolate panning

- CHAPTER 17: Chocolate rework

- CHAPTER 18: Artisan chocolate making

- CHAPTER 19: Chocolate compounds andcoatings

- CHAPTER 20: Recipes

- CHAPTER 21: Sensory evaluation of chocolate and cocoa products

- CHAPTER 22: Nutritional and health aspects of chocolate

- CHAPTER 23: Quality control and shelf life

- CHAPTER 24: Instrumentation

- CHAPTER 25: Food safety in chocolate manufacture and processing

- CHAPTER 26: Packaging

- CHAPTER 27: The global chocolate confectionery market

- CHAPTER 28: Legal aspects of chocolate manufacture

- CHAPTER 29: Intellectual property

- CHAPTER 30: Future trends

- Glossary

- Useful physical constants

- Index

- End User License Agreement