- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

Biodegradable Green Composites

About this book

This book comprehensively addresses surface modification of natural fibers to make them more effective, cost-efficient, and environmentally friendly. Topics include the elucidation of important aspects surrounding chemical and green approaches for the surface modification of natural fibers, the use of recycled waste, properties of biodegradable polyesters, methods such as electrospinning, and applications of hybrid composite materials.

Tools to learn more effectively

Saving Books

Keyword Search

Annotating Text

Listen to it instead

Information

1

BIODEGRADABLE GREEN COMPOSITES

Sreerag Gopi1,2, Anitha Pius1, and Sabu Thomas2

1 Gandhigram Rural University—Deemed University, Dindigul, Tamil Nadu, India

2 International and Inter University Centre for Nanoscience and Nanotechnology, Mahatma Gandhi University, Kottayam, Kerala, India

1.1 INTRODUCTION

Conventional polymers are usually made from petroleum resources such as polyolefins, and they are ideal for many applications such as packaging, building resources, commodities, and consumer goods. Polyolefin-based plastics have become a foundation of modern civilization and are low cost, durable, resistant to solvents, waterproof, and resistant to physical aging. The resistance of polyolefin materials to degradation by microorganisms is both an advantage and, in the long term, a problem. It was estimated in 2002 that some 41%·w/w of the total global plastic production was used by packaging industries, with 47% of that production being used to package foodstuffs [1]. Most oil-derived packaging is nonrecyclable, or economically impractical to recycle, and quickly becomes landfill, equating to a huge quantity of nondegradable waste. Microorganisms found in landfill soils are unable to degrade conventional plastics [2], and as a result, they remain in the environment for a very long time [3]. This in itself has not been a huge concern until recently. Landfills are unattractive to residents living near them, and new ones are costly and difficult to establish. Landfills are becoming filled to capacity with more waste generated every day due to continued expansion of human urban areas and population increases. Recycling plastics is one possible solution, and since the early 1990s, more and more plastic waste is subject to recycling across developed nations [4, 5]. Australia recycled 18.5% (282,032 t) of the total plastics collected in 2008, and 58.2% of that amount was recycled here with the remainder exported for reprocessing [6]. Despite this admirable effort, it still leaves a phenomenal amount of waste plastics. Recycling is not without its problems since often recycled polymers are contaminated, resulting in inferior mechanical properties to feedstock created ones [7]. This reduces recycled feedstock desirability and hence the economic benefit to recycling. Polymer waste can also be disposed of by incineration, but given the current political climate on greenhouse emissions, this is becoming unfeasible. Incineration also produces harmful gasses and emissions, for example, burning poly(vinyl chloride) (PVC) produces furans and dioxins [8]. In this context, green composites gain their importance.

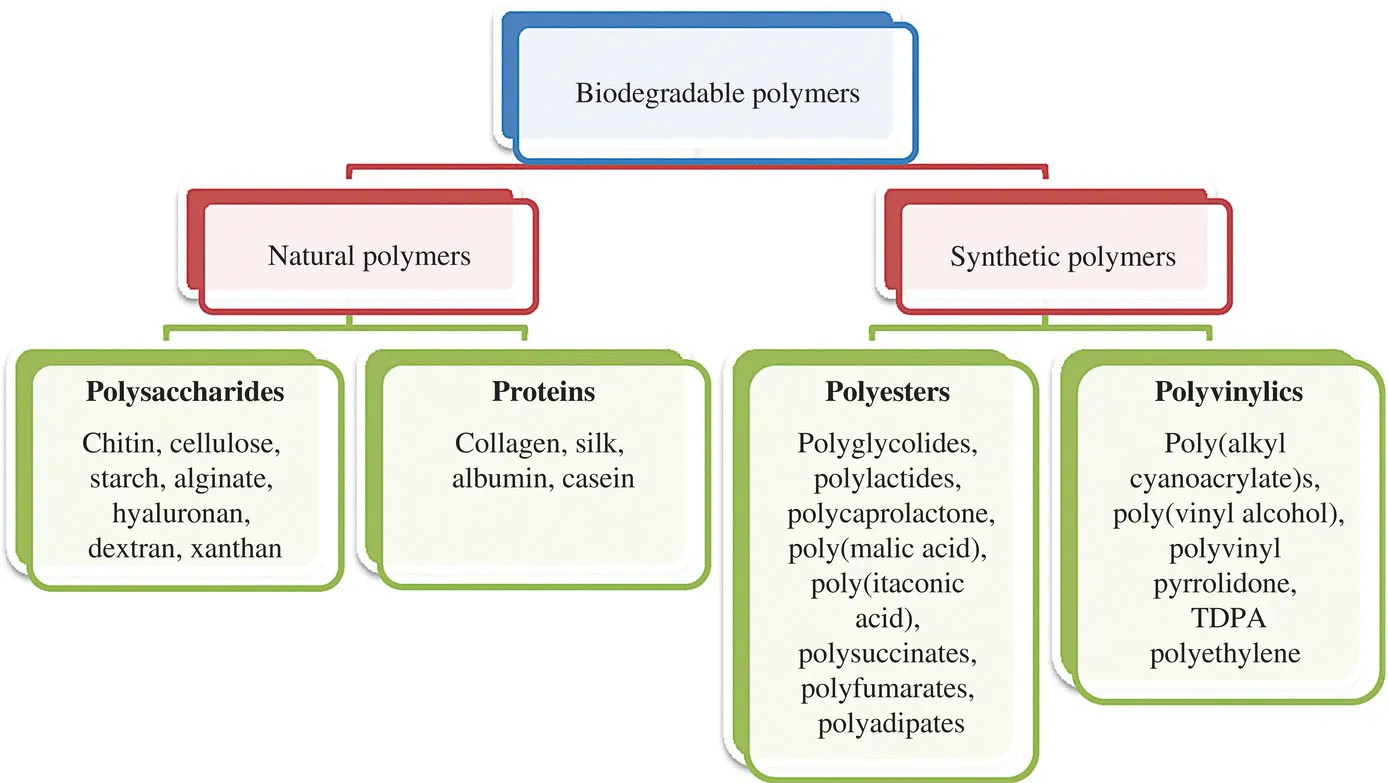

Figure 1.1 shows a classification of biodegradable polymers mainly in two families. A large number of these biodegradable polymers (biopolymers) are commercially available. They show a large range of properties, and they can compete with nonbiodegradable polymers in different industrial fields (e.g., packaging).

FIGURE 1.1 Classification of biodegradable polymers in four families.

1.2 BIODEGRADABLE POLYMERS

1.2.1 Starch

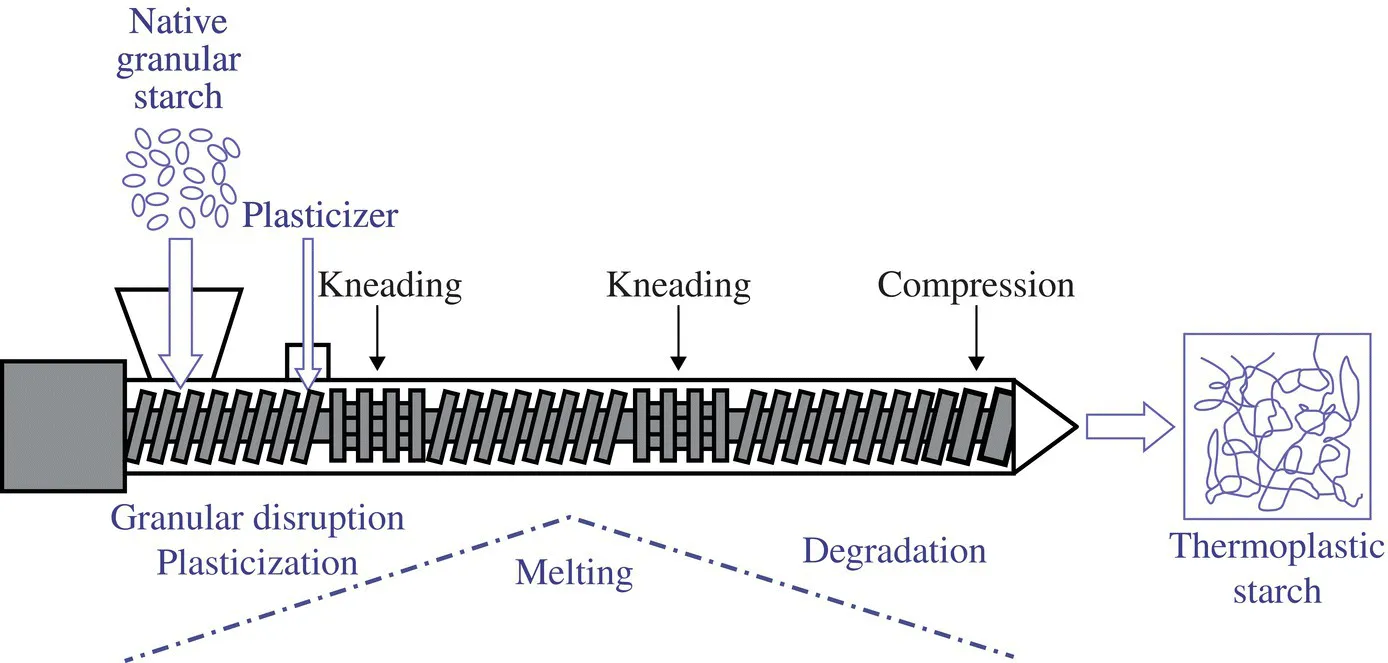

Starch is a widely used bioplastic that is actually a storage polysaccharide in plants. It is composed of both linear and branched polysaccharides known as amylose and amylopectin, respectively. The ratio of these polysaccharides varies with their botanical origin, and generally, native starches contain around 85–70% amylopectin and 15–30% amylose. Starch softening temperature is higher than its degradation temperature due to the presence of many intermolecular hydrogen bonds [9], which affects its processing. Plasticizers like water, glycerol, and sorbitol will help in increasing the free volume and thereby decreasing the glass transition and softening temperatures [10]. The schematic showing the process of obtaining TPS is shown in Figure 1.2. Traditional extrusion, injection molding, and compression molding can be used to process thermoplastic starch. The melt processing technique of obtaining thermoplastic starch is a complex operation that involves plasticization, devolatilization, melt–melt mixing, and morphology control. The final morphology of TPS depends on composition, mixing time, temperature, shear, and elongation rate of the operation. Although it is possible to make useful products from TPS alone, extreme moisture sensitivity of starch leads to limited practical application. Therefore, the reality in commercialization of starch-based plastics involves blending of TPS with other polymers and additives. Thermoplastic starch formation [11] is shown in Figure 1.2.

FIGURE 1.2 Thermoplastic starch formation.

Source: Xie et al. [11], figure 37. Reproduced with permission from Elsevier. Copyright 2015.

1.2.2 Cellulose

Cellulose is an abundant and ubiquitous natural polymer. It is the major structural component of plant cells and is found throughout nature. It is widely used in industrial applications in different forms. Cellulose is mostly obtained from wood and cotton at present for many applications; on the other hand, cellulose pulp is also being extracted from agricultural by-products such as bagasse, stalks, and crop straws. Currently, cellulose-based materials are used in two forms on an industrial scale [12]:

- Regenerated cellulose is used for fiber and film production and cannot be melt processed.

- Cellulose esters are used in a broad array of applications including coatings, biomedical uses, and other usual plastic applications.

Nonplant resources can also be used to produce cellulose, es...

Table of contents

- COVER

- TITLE PAGE

- TABLE OF CONTENTS

- CONTRIBUTORS

- PREFACE

- 1 BIODEGRADABLE GREEN COMPOSITES

- 2 SURFACE MODIFICATION OF NATURAL FIBERS USINGPLASMA TREATMENT

- 3 REINFORCING POTENTIAL OF ENZYMATICALLY MODIFIED NATURAL FIBERS

- 4 RECENT DEVELOPMENTS IN SURFACE MODIFICATION OF NATURAL FIBERS FOR THEIR USE IN BIOCOMPOSITES

- 5 NANOCELLULOSE-BASED GREEN NANOCOMPOSITE MATERIALS

- 6 POLY(LACTIC ACID) HYBRID GREEN COMPOSITES

- 7 LIGNIN/NANOLIGNIN AND THEIR BIODEGRADABLE COMPOSITES

- 8 STARCH-BASED “GREEN” COMPOSITES

- 9 GREEN COMPOSITE MATERIALS BASED ON BIODEGRADABLE POLYESTERS

- 10 APPLICATIONS OF GREEN COMPOSITE MATERIALS

- INDEX

- END USER LICENSE AGREEMENT

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn how to download books offline

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 990+ topics, we’ve got you covered! Learn about our mission

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more about Read Aloud

Yes! You can use the Perlego app on both iOS and Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Yes, you can access Biodegradable Green Composites by Susheel Kalia in PDF and/or ePUB format, as well as other popular books in Technology & Engineering & Environmental Science. We have over one million books available in our catalogue for you to explore.