eBook - ePub

Energy Management and Efficiency for the Process Industries

This is a test

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

Energy Management and Efficiency for the Process Industries

Book details

Book preview

Table of contents

Citations

About This Book

Provides a unique overview of energy management for the process industries

- Provides an overall approach to energy management and places the technical issues that drive energy efficiency in context

- Combines the perspectives of freewheeling consultants and corporate insiders

- In two sections, the book provides the organizational framework (Section 1) within which the technical aspects of energy management, described in Section 2, can be most effectively executed

- Includes success stories from three very different companies that have achieved excellence in their energy management efforts

- Covers energy management, including the role of the energy manager, designing and implementing energy management programs, energy benchmarking, reporting, and energy management systems

- Technical topics cover efficiency improvement opportunities in a wide range of utility systems and process equipment types, as well as techniques to improve process design and operation

Frequently asked questions

At the moment all of our mobile-responsive ePub books are available to download via the app. Most of our PDFs are also available to download and we're working on making the final remaining ones downloadable now. Learn more here.

Both plans give you full access to the library and all of Perlego’s features. The only differences are the price and subscription period: With the annual plan you’ll save around 30% compared to 12 months on the monthly plan.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 1000+ topics, we’ve got you covered! Learn more here.

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more here.

Yes, you can access Energy Management and Efficiency for the Process Industries by Alan P. Rossiter, Beth P. Jones, Alan P. Rossiter, Beth P. Jones in PDF and/or ePUB format, as well as other popular books in Tecnología e ingeniería & Ingeniería química y bioquímica. We have over one million books available in our catalogue for you to explore.

Information

Section 1

Energy Management Programs

1

Energy Management in Practice

Beth P. Jones

LyondellBasell (Retired), Guildford, Surrey, UK

Attention to energy efficiency seems to rise and fall in corporate priority with both the rise and fall of energy prices and the rise and fall in manufacturing margins. The life of the corporate energy manager is much the same. If energy costs are high and margins are slim, you are the man or woman of the hour, and if times are good and natural gas supplies are booming, no one will return your calls. Resources are allocated similarly. Bad times and poor prospects for capital spending free up lots of people to look for opportunities for more efficient operations. When times are better, those human resources are reallocated to opportunities with higher expected returns. A well thought-out energy management program identifies opportunities, sets the bar for ongoing performance, and maintains improvements with a minimum of resources. Otherwise, over time and with reduced scrutiny, efficiencies decline and relative costs go up. A few years later, the cycle repeats itself and a new team relearns all the lessons from the last cycle.

Several years ago, a technician received the company's highest “attaboy” award from its then president. His achievement included tuning up all the company's huge olefin furnaces and saving millions of dollars per year in energy costs. To quote the president's comment in this regard, “Great job rediscovering what we already knew! Next time maybe we'll just punish the people who stopped doing it.” The technician took the comment to heart and wrote a “Furnace Manifesto” to preserve and institutionalize the knowledge.

This book is intended to provide an overview of industrial energy management, particularly for the process industries. Section 1 is focused on management issues—how to start and maintain an effective program, identify the components of a successful program, benchmark, and create management systems—and case studies that provide practical insights from successful and experienced energy managers. The rest of the book provides expert technical help in what to do to save energy, with particular focus on the energy users most significant to the process industries.

This chapter describes a practical overall approach to starting an energy management program and identifying and implementing energy efficiency improvements in a sustainable way. The chapter is particularly focused on helping new energy managers get started: What do they need to know to be effective in their role? Since most of these issues are also relevant to experienced managers and engineers with energy management responsibilities, we hope it will also be useful to all readers.

Assessing the Value of An Energy Management Program

In most process industries, energy costs are second only to raw material costs. Entire departments are devoted to optimizing raw material choices and product slates, using planning models, supply strategies, and online optimization. Apart from buying energy at the lowest possible cost, most companies also consider energy to be an inevitable cost of doing business. However, energy use is not just a concern for the utilities department, and you, as an energy manager, must separate the cost of doing business from the cost of doing business well. Other benefits flow from focusing on energy, such as a reduced environmental impact and a cultural change toward reducing waste, but the scope of any energy management program is determined by its economic value.

Determine your company's energy use and energy cost, beginning with large sections of the organization and drilling down as far as it is practical. Use the data that are available now and are already understood by the organization. Energy information can come from site utility bills, internal cost accounting, and/or the utilities procurement group. Often the search for the data is as enlightening as the actual data. Was the information easy or difficult to collect? What does it tell you about each site? Are total company or division costs combined and analyzed already?

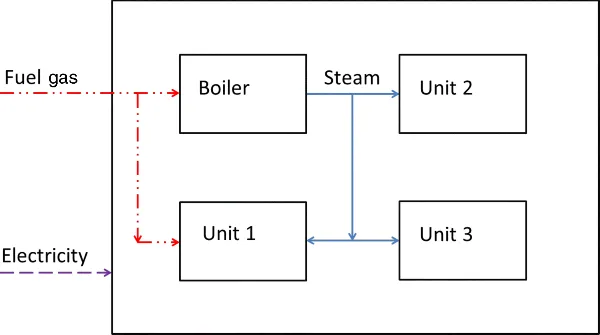

Draw a material balance box around each unit, site, or division, based on the details that are available (Figure 1.1). Include all external sources of energy that cross the boundary, such as purchased electric power, fuel gas, solid or liquid fuel, purchased steam, or whatever else is consumed within the box. If feed or product streams are burned or consumed to produce energy, include those as well. Collect both the nameplate capacity of each unit and its average operating rate.

Figure 1.1 A simple material balance provides great insights into overall energy usage.

- Site energy use = fuel gas rate × heating value + electricity rate

- Site energy cost = fuel gas rate × price + electricity rate × electricity price

- Site-specific energy use = site energy use/average feed(or major product)rate

Now that you have an initial fix on the company's energy profile, you can proceed toward estimating the value of potential energy savings with a combination of data and engineering judgment. From industry publications or data searches, determine the benchmark-specific energy use for the technologies in each box, and scale the specific energy to the nameplate capacity of each process. Chapter 5 gives a more detailed look at benchmarking.

Subtract the actual energy use from the benchmark use for each box and add up the potential savings. If no benchmark is available or the available data are not detailed enough to apply a benchmark, choose a reasonable percentage of current use. If no energy improvement program was active in the last 5–10 years, a 10% saving is feasible. Even relatively new and efficient units generally have a bit of refinement available (1–2%) through active energy management.

Compare your estimate of potential savings with the current total energy bill.

Can you afford to focus some resources on energy? Can you afford not to?

Launching the Program

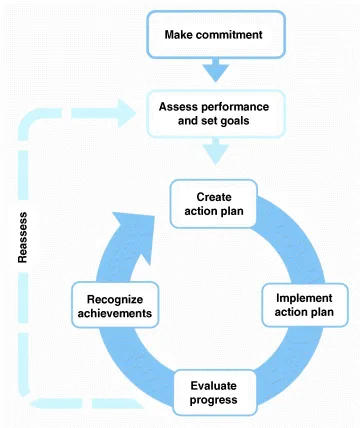

Like most corporate objectives, energy efficiency goals need support from above and heavy lifting from below. Managers will not generally support a new initiative unless they think that the issue is important enough to displace other priorities, and benefits cannot be achieved unless people are motivated to work toward them. An energy management program is a circular process of identifying opportunities, scoping solutions, and implementing improvements, and by doing so, refining the view for another pass (Figure 1.2). Getting started is the important thing. Significant energy improvements can be achieved without the final polishing of the process, so do not lose the good enough in pursuit of the perfect. Early successes prove that focusing on energy is worthwhile and inspire people to go out and look for opportunities in their areas.

Figure 1.2 The “circular process” of energy management. (Source: www.energystar.gov/guidelines)

Starting a program can be easier if you begin at the top. Presumably, upper management has both the vision to see the benefits of energy efficiency and command of the resources needed to do the work. Management commitment is key to the success of the effort. An energy policy statement from the executives demonstrates that commitment and provides the justification to get every site involved in the energy management process.

Some groundwork is necessary before you present your request for support. It is not enough just to estimate potential savings. You will need a rough action plan and an idea of the resources needed to achieve the savings in a given time. Data, plans, and resource requirements will improve with time and study, but first you must get the program off the ground.

Your credibility will also be enhanced by some judicious energy information gathering. You may encounter people within your company who do not believe that significant improvements in energy use are possible. Show them what your competitors are doing. Most large corporations discuss their energy improvements, and the resulting environmental improvements, on their websites. Case studies of successful programs from three companies in very different businesses and with very different energy usage profiles are discussed in Chapters 2–4. Energy policy statements are also displayed on corporate websites. Public organizations, such as ENERGY STAR from the U.S. Environmental Protection Agency (Chapter...

Table of contents

- Cover

- Title Page

- Copyright

- Foreword

- Preface

- Acknowledgments

- Contributors

- Units of Measure

- Section 1: Energy Management Programs

- Section 2: Energy Management Technologies

- Equipment

- Utility Systems

- Process

- Index

- End User License Agreement