Corrosion and Materials in Hydrocarbon Production

A Compendium of Operational and Engineering Aspects

- English

- ePUB (mobile friendly)

- Available on iOS & Android

Corrosion and Materials in Hydrocarbon Production

A Compendium of Operational and Engineering Aspects

About This Book

Comprehensively covers the engineering aspects of corrosion and materials in hydrocarbon production

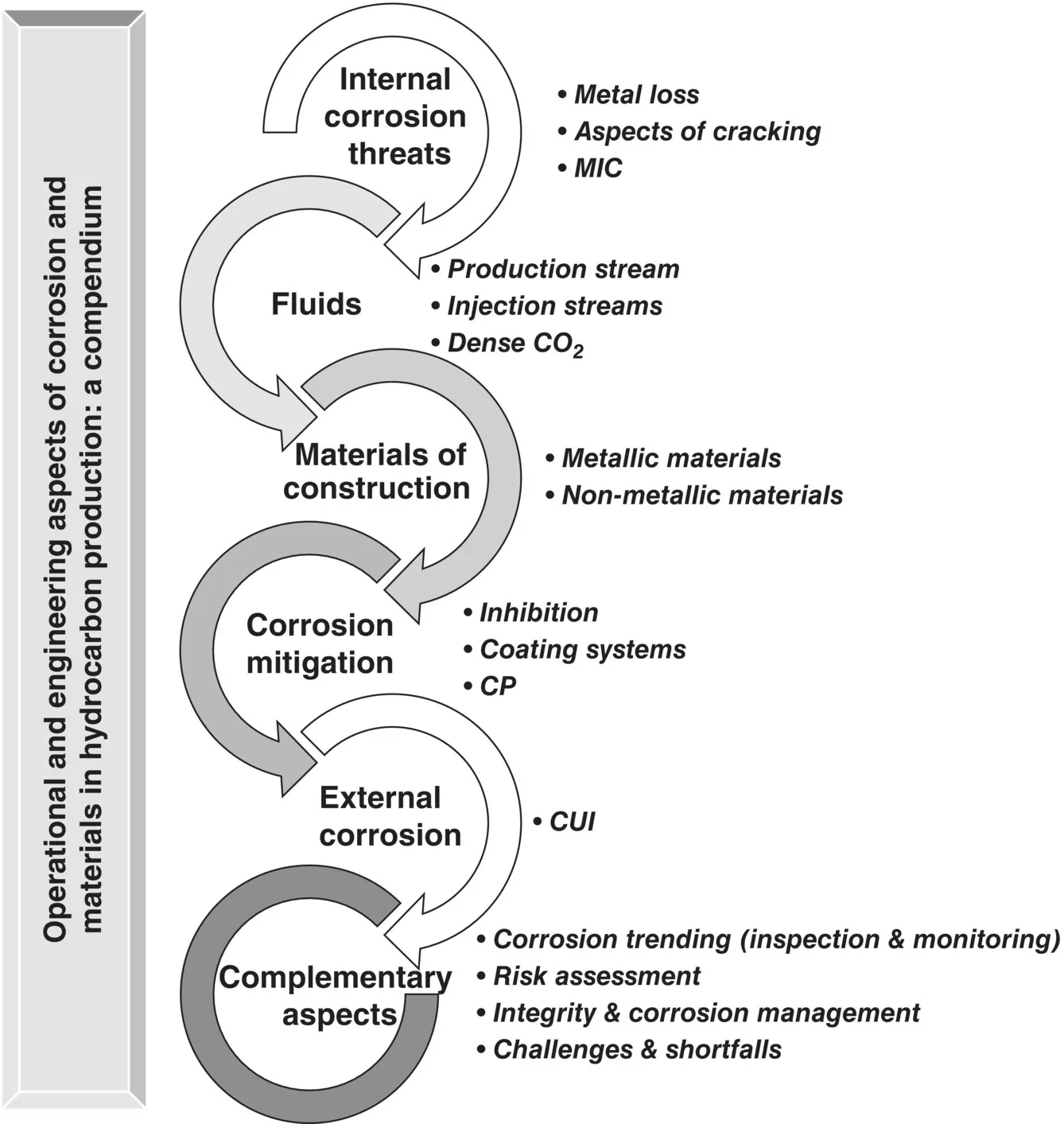

This book captures the current understanding of corrosion processes in upstream operations and provides a brief overview of parameters and measures needed for optimum design of facilities. It focuses on internal corrosion occurring in hydrocarbon production environments and the key issues affecting its occurrence, including: the types and morphology of corrosion damage; principal metallic materials deployed; and mitigating measures to optimise its occurrence. The book also highlights important areas of progress and challenges, and looks toward the future of research and development to enable improved and economical design of facilities for oil and a gas production.

Written for both those familiar and unfamiliar with the subject—and by two authors with more than 60 years combined industry experience—this book covers everything from Corrosion Resistant Alloys (CRAs) to internal metal loss corrosion threats, corrosion in injection systems to microbiologically influenced corrosion, corrosion risk analysis to corrosion and integrity management, and more, notably:

- Comprehensively covers the engineering aspects of corrosion and materials in hydrocarbon production

- Written by two, renowned experts in the field

- Offers practical guide to those unfamiliar with the subject whilst providing a focused roadmap to addressing the topics in a precise and methodical manner

- Covers all aspects of corrosion threat and remedial and mitigation measures in upstream hydrocarbon production applicable to sub-surface, surface, and transportation facilities

- Outlines technology challenges that need further research as a pre-cursor to moving the industry forward.

Operational and Engineering Aspects of Corrosion and Materials in Hydrocarbon Production is an excellent guide for both practicing materials and corrosion engineers working in hydrocarbons production as well as those entering the area who may not be fully familiar with the subject.

Frequently asked questions

Information

1

Introduction

- the impact of corrosion, highlighting its economic implications;

- types of corrosion threats in oil and gas production and transportation, the manner in which they manifest, and the means of their control and design;

- where future priorities need to be set to sustain and develop the continuing fitness‐for‐purpose of the practice and status of the corrosion and materials discipline.

1.1 Scope and Objectives

- Corrosion threats and their respective assessment practices and mitigation methods.

- Corrosion interrogation methods, including monitoring and inspection data capture and full analysis.

- Methods by which materials are selected for a particular application.

- Determining corrosion risk and implications with respect to defining safe operational conditions and the implementation of mitigation methods, measures and practice as an integral part of a fit‐for‐purpose corrosion and integrity management strategy.

- Consideration of current and future challenges to those engineers who wish to specialise in materials and corrosion knowledge, and outlining the gaps in best implementation of know‐how and knowledge.

1.1.1 Contents of the Book

1.2 The Impact of Corrosion

Table of contents

- Cover

- Table of Contents

- Preface

- Acknowledgement

- 1 Introduction

- 2 Carbon and Low Alloy Steels (CLASs)

- 3 Corrosion‐Resistant Alloys (CRAs)

- 4 Water Chemistry

- 5 Internal Metal Loss Corrosion Threats

- 6 Environmental Cracking (EC)

- 7 Corrosion in Injection Systems

- 8 Corrosion Mitigation by the Use of Inhibitor Chemicals

- 9 Coating Systems

- 10 Corrosion Trending

- 11 Microbiologically Influenced Corrosion (MIC)

- 12 Dense Phase CO2 Corrosion

- 13 Corrosion Under Insulation (CUI)

- 14 Metallic Materials Optimisation Routes

- 15 Non‐metallic Materials: Elastomer Sealsand Non‐metallic Liners

- 16 Cathodic Protection (CP)

- 17 Corrosion Risk Analysis

- 18 Corrosion and Integrity Management

- 19 Corrosion and Materials Challenges in Hydrocarbon Production

- Abbreviations

- Index

- End User License Agreement