- English

- ePUB (mobile friendly)

- Available on iOS & Android

About This Book

This book details the basic concepts and the design rules included in Eurocode 3

- Design of steel structures: Part 1-8

- Design of joints

- Joints in composite construction are also addressed through references to Eurocode 4

- Design of composite steel and concrete structures

- Part 1-1: General rules and rules for buildings.

Attention has to be duly paid to the joints when designing a steel or composite structure, in terms of the global safety of the construction, and also in terms of the overall cost, including fabrication, transportation and erection. Therefore, in this book, the design of the joints themselves is widely detailed, and aspects of selection of joint configuration and integration of the joints into the analysis and the design process of the whole construction are also fully covered.

Connections using mechanical fasteners, welded connections, simple joints, moment-resisting joints and lattice girder joints are considered. Various joint configurations are treated, including beam-to-column, beam-to-beam, column bases, and beam and column splice configurations, under different loading situations (axial forces, shear forces, bending moments and their combinations).

The book also briefly summarises the available knowledge relating to the application of the Eurocode rules to joints under fire, fatigue, earthquake, etc., and also to joints in a structure subjected to exceptional loadings, where the risk of progressive collapse has to be mitigated.

Finally, there are some worked examples, plus references to already published examples and to design tools, which will provide practical help to practitioners.

Frequently asked questions

Information

Chapter 1

INTRODUCTION

1.1 GENERAL

1.1.1 Aims of the book

- – To provide designers with practical guidance and tools for the design of steel and composite joints;

- – To point out the importance of structural joints on the response of steel and composite structures and to show how the actual behaviour of joints may be incorporated into the structural design and analysis process;

- – To illustrate the possibilities of producing more economical structures using the new approaches offered in Eurocode 3 and Eurocode 4 as far as structural joints are concerned.

- – Presentation and discussion of concepts;

- – Practical guidance and design tools.

1.1.1.1 The traditional common way in which joints are modelled for the design of a frame

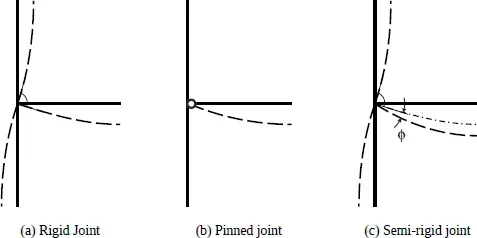

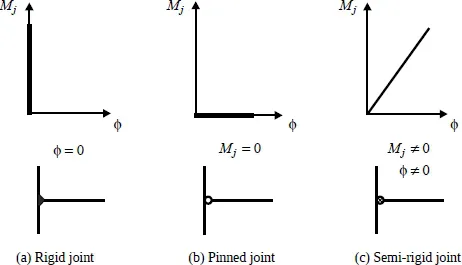

- – Frame modelling including the choice of rigid or pinned joints;

- – Initial sizing of beams and columns;

- – Evaluation of internal forces and moments (load effects) for each ultimate limit state (ULS) and serviceability limit state (SLS) load combination;

- – Design checks of ULS and SLS criteria for the structure and the constitutive beams and columns;

- – Iteration on member sizes until all design checks are satisfactory;

- – Design of joints to resist the relevant members end forces and moments (either those calculated or the maximum ones able to be transmitted by the actual members); the design is carried out in accordance with the prior assumptions (frame modelling) on joint stiffness.

1.1.1.2 The semi-continuous approach

Table of contents

- Cover

- Table of Contents

- Series

- Title

- Copyright

- FOREWORD

- PREFACE

- LIST OF SYMBOLS AND ABBREVIATIONS

- Chapter 1: INTRODUCTION

- Chapter 2: STRUCTURAL ANALYSIS AND DESIGN

- Chapter 3: CONNECTIONS WITH MECHANICAL FASTENERS

- Chapter 4: WELDED CONNECTIONS

- Chapter 5: SIMPLE JOINTS

- Chapter 6: MOMENT RESISTANT JOINTS

- Chapter 7: LATTICE GIRDER JOINTS

- Chapter 8: JOINTS UNDER VARIOUS LOADING SITUATIONS

- Chapter 9: DESIGN STRATEGIES

- BIBLIOGRAPHIC REFERENCES

- Annex A: Practical values for required rotation capacity

- Annex B: Values for lateral torsional buckling strength of a fin plate

- End User License Agreement