From Prognostics and Health Systems Management to Predictive Maintenance 1

Monitoring and Prognostics

- English

- ePUB (mobile friendly)

- Available on iOS & Android

From Prognostics and Health Systems Management to Predictive Maintenance 1

Monitoring and Prognostics

About This Book

This book addresses the steps needed to monitor health assessment systems and the anticipation of their failures: choice and location of sensors, data acquisition and processing, health assessment and prediction of the duration of residual useful life. The digital revolution and mechatronics foreshadowed the advent of the 4.0 industry where equipment has the ability to communicate. The ubiquity of sensors (300, 000 sensors in the new generations of aircraft) produces a flood of data requiring us to give meaning to information and leads to the need for efficient processing and a relevant interpretation. The process of traceability and capitalization of data is a key element in the context of the evolution of the maintenance towards predictive strategies.

Frequently asked questions

Information

1

PHM and Predictive Maintenance

1.1. Anticipative maintenance and prognostics

1.1.1. New challenges and evolution of the maintenance function

1.1.1.1. Industrial maintenance

1.1.1.2. Challenges and prerogatives of the maintenance function

- – It aims to increment the equipment availability while reducing the direct exploitation costs (technical and economic).

- – It has to ensure a safe operation of equipment, namely avoiding accidents which can be judged as detrimental to the environment (environmental).

- – It is responsible for satisfactory work conditions and for human safety (social).

1.1.1.3. Evolution of the maintenance function

1.1.2. Towards an anticipation of failure mechanisms

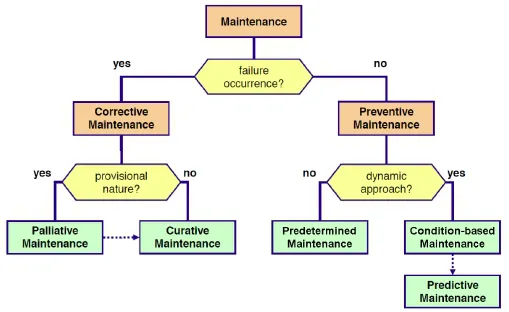

1.1.2.1. Cartography of maintenance forms

1.1.2.2. Corrective and preventive maintenances

- – the consequences of the breakdown are not critical,

- – the repairs are easy and does not require a lot of time and

- – the investment costs are low.

Table of contents

- Cover

- Table of Contents

- Title

- Copyright

- Introduction

- 1 PHM and Predictive Maintenance

- 2 Acquisition: From System to Data

- 3 Processing: From Data to Health Indicators

- 4 Health Assessment, Prognostics and Remaining Useful Life - Part A

- 5 Health Assessment, Prognostics, and Remaining Useful Life - Part B

- Conclusion and Open Issues

- Bibliography

- Index

- End User License Agreement