This is a test

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

Book details

Book preview

Table of contents

Citations

About This Book

Recycling of Polymers

This timely reference on the topic is the only book you need for a complete overview of recyclable polymers.

Following an introduction to various polymer structures and their resulting properties, the main part of the book deals with different methods of recycling. It discusses in detail the recycling of such common polymers as polyethylene, polypropylene and PET, as well as rubbers, fibers, engineering polymers, polymer blends and composites. The whole is rounded off with a look at future technologies and the toxicological impact of recycled polymers.

An indispensable reference source for those working in the field, whether in academia or industry, and whether newcomers or advanced readers.

Frequently asked questions

At the moment all of our mobile-responsive ePub books are available to download via the app. Most of our PDFs are also available to download and we're working on making the final remaining ones downloadable now. Learn more here.

Both plans give you full access to the library and all of Perlego’s features. The only differences are the price and subscription period: With the annual plan you’ll save around 30% compared to 12 months on the monthly plan.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 1000+ topics, we’ve got you covered! Learn more here.

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more here.

Yes, you can access Recycling of Polymers by Raju Francis in PDF and/or ePUB format, as well as other popular books in Technologie et ingénierie & Gestion de l'environnement. We have over one million books available in our catalogue for you to explore.

Information

Chapter 1

Introduction

Raju Francis, Geethy P. Gopalan and Anjaly Sivadas

Mahatma Gandhi University, School of Chemical Sciences, Priyadarsini Hills, Kottayam, Kerala, 686560, India

“Recycling saves energy, preserves natural resources, reduces greenhouse-gas emissions, and keeps toxins from leaking out of landfills.”

–Marc Gunther

1.1 Introduction

1.1.1 Why Recycling?

During the past decades, the enormous population increase worldwide, together with the need for people to adopt improved conditions of living, has led to a dramatic increase of the consumption of polymers (mainly plastics). Materials appear interwoven with our consumer society, where it would be hard to imagine living without plastics, which have found a myriad of uses in fields as diverse as household appliances, packaging, construction, medicine, electronics, and automotive and aerospace components. The unabated increase in the use of plastics has led to an increase in the quantity of plastics ending up in the waste stream, which has stimulated intense interest in the recycling and reuse of plastics [1]. Worldwide, the production of plastics was 168 million tons in the year 1999 and approximately 210 million tons in 2010 .

Since the treatment of plastic wastes has become a serious problem, the development of effective recycling processes is urgently needed [2].

1.1.2 Sources of Waste

Plastics play an important role in almost every aspect of our lives. Plastics are used to manufacture products of daily use such as beverage containers, toys, and furniture. The widespread use of plastics demands proper end-life management [3]. A large number of items can be easily recycled in most curbside programs, including all kinds of paper and cardboard, glass of all colors and types, plastic bottles, aluminum cans, and yard trimmings. In addition, a number of localities offer drop-off programs for recycling other items, such as household hazardous wastes (paints, cleaners, oils, batteries, and pesticides), automobile items (tires, used engine oil, car batteries, antifreeze), wood construction materials, certain metals, appliances, and consumer electronics [4].

The largest amount of plastics is found in containers and packaging (e.g., soft drink bottles, lids, shampoo bottles), but they also are found in durables (e.g., appliances, furniture) and nondurables (e.g., diapers, trash bags, cups, utensils, and medical devices). Commercial waste is often produced by workshops, craftsmen, shops, supermarkets, and wholesalers. Agricultural waste can be obtained from farm and nursery gardens outside the urban areas. This is usually in the form of packaging (plastic containers or sheets) or construction materials (irrigation or hosepipes). Municipal waste can be collected from residential areas (domestic or household waste), streets, parks, collection depots, and waste dumps [5].

Around 50% of plastics are used for single-use disposable applications, such as packaging, agricultural films, and disposable consumer items; between 20% and 25% for long-term infrastructure such as pipes, cable coatings, and structural materials; and the remainder for durable consumer applications with intermediate lifespan, such as in electronic goods, furniture, and vehicles [6].

1.1.3 Plastics

Plastics are made up of polymers and other materials that are added to give the polymer increased functionality. The polymer content in a plastic can vary widely from less than 20% to nearly 100%. Those plastics consisting virtually entirely of polymers are termed prime grades. The level and type of the other additives used depend on the application for which the plastic is intended. Plastics are inexpensive, lightweight, and durable materials, which can readily be molded into a variety of products that find use in a wide range of applications. As a consequence, the production of plastics has increased markedly over the last 60 years [6]. Thermosets and thermoplastics are the two major classifications of plastics. This distinction is based on both the molecular structure and the processing routes that can be applied. It also relates to recycling routes, as each category needs a different approach to utilize its recovery potential. Thermoplastics and thermosets will now be discussed.

- ThermoplasticsThese materials melt and flow when heated and solidify when cooled. On subsequent reheating, they melt and regain the ability to flow. This means that they can be used again and hence recycled by remelting them. Thermoplastics are used to make consumer items such as drinks containers, carrier bags, and buckets.

- ThermosetsThese materials are processed by melting, often in a similar manner to thermoplastics. However, once formed and cooled, they cannot be reprocessed; they decompose before they can melt. This is because they are chemically crosslinked by a process termed curing. The material becomes stiff and brittle with a highly dense molecular network [7].

1.1.4 Recycling of Plastics

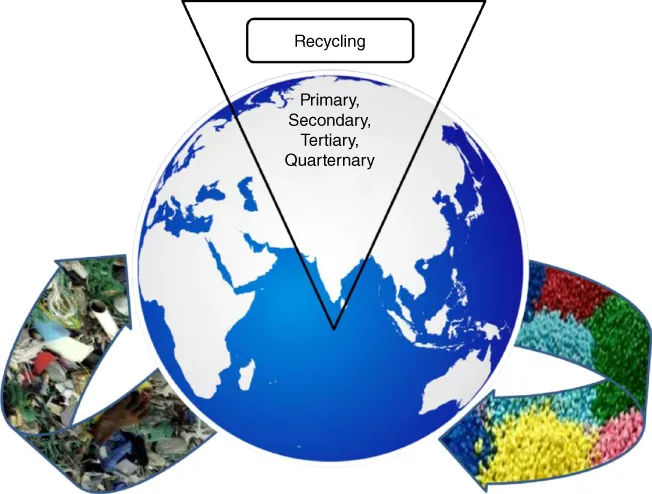

Recycling of plastics is one method for reducing environmental impact and resource depletion. Recycling can therefore decrease energy and material usage per unit of output, leading to improved eco-efficiency. The only way to decrease the environmental problems caused by polymeric waste accumulation produced from day-to-day applications of polymer materials such those used in packaging and construction is by recycling. This helps to conserve natural resources because most polymer materials are made from oil and gas [8].

Recycling is the final result of the intermediate stages of collection, sorting by type, and processing of polymers. It reduces the quantity of residues in landfills and those indiscriminately discarded in the environment. Thus, it also leads to a reduction of problems such as the spread of diseases as well as contamination of soil, air, and water bodies [9]. It is one of the most important options currently available to reduce these impacts and represents one of the most dynamic areas in the plastics industry today. It provides opportunities to reduce oil usage, carbon dioxide emission, and the quantities of waste requiring disposal.

Recycling plastics encompasses four phases of activity, namely collection, separation, processing, and manufacturing and marketing. Because only the use of clean, homogeneous resins can produce the highest quality recycled plastic products in the existing secondary process (material recycling) and high-value chemical products in the existing tertiary process (feedstock recycling) [10], an effective separation of mixed plastics waste is necessary.

1.1.5 Municipal Solid Waste

The growth of plastics waste has a great impact on the management of municipal solid waste (MSW) by landfilling and incineration, because the available capacity for landfill of MSW is declining and plastics incineration may cause emission and toxic fly and bottom ash containing lead and cadmium [10]. Plastics waste recycling is a method of reducing the quantity of net discards of MSW. Although the benefits have not been quantified, plastics recycling also offer the potential to generate demonstrable savings in fossil fuel consumption, both because the recycled plastics can supplement and even compete with “virgin” resins produced from refined fossil fuel and because the energy required to yield recycled plastics may be less than that consumed in the production of the same resins from virgin feedstock. Therefore, plastics waste recycling conserves both material and energy and provides a comparatively simple way to make a substantial reduction in the overall volume of MSW [11].

The major plastics recycled are polyolefins (high-density polyethylene (HDPE), low-density polyethylene (LDPE), and polypropylene (PP)) and poly(ethylene terephthalate) (PET), poly(vinyl chloride) (PVC), polystyrene (PS), and polycarbonate (PC). The recyclable polymers and the recycling codes are shown in Table 1.1.

Table 1.1 Various polymers with their characteristic recycling codes for ...

Table of contents

- Cover

- Title Page

- Copyright

- Table of Contents

- Preface

- List of Contributors

- Abbreviations

- Chapter 1: Introduction

- Chapter 2: Common Additives used in Recycling of Polymers

- Chapter 3: Methods of Recycling

- Chapter 4: Recycling of Plastics

- Chapter 5: Recycling of Rubber

- Chapter 6: Fibers

- Chapter 7: Recycling of Polymer Blends and Composites (Epoxy Blends)

- Chapter 8: Recycling of Other Layered Mixed Plastics or Resins: Polyurethanes

- Chapter 9: Ecoprofiles of Recycled Polymers at a Glance

- Index

- End User License Agreement