eBook - ePub

Polymeric Foams

Innovations in Technologies and Environmentally Friendly Materials

S.-T. Lee, S.-T. Lee

This is a test

- 318 pagine

- English

- ePUB (disponibile sull'app)

- Disponibile su iOS e Android

eBook - ePub

Polymeric Foams

Innovations in Technologies and Environmentally Friendly Materials

S.-T. Lee, S.-T. Lee

Dettagli del libro

Anteprima del libro

Indice dei contenuti

Citazioni

Informazioni sul libro

Polymeric Foams: Innovations in Technologies and Environmentally Friendly Materials offers the latest in technology and environmental innovations within the field of polymeric foams. It outlines how application-focused research in polymeric foam can continue to improve living quality and enhance social responsibility.

This book:

-

- Addresses technological innovations including those in bead foams, foam injection molding, foams in tissue engineering, foams in insulation, and silicon rubber foam

-

- Discusses environmentally friendly innovations in PET foam, degradable and renewable foam, and physical blowing agents

-

- Describes principles as well as applications from internationally recognized foam experts

This work is aimed at researchers and industry professionals across chemical, mechanical, materials, polymer engineering, and anyone else developing and applying these advanced polymeric materials.

Domande frequenti

Come faccio ad annullare l'abbonamento?

È semplicissimo: basta accedere alla sezione Account nelle Impostazioni e cliccare su "Annulla abbonamento". Dopo la cancellazione, l'abbonamento rimarrà attivo per il periodo rimanente già pagato. Per maggiori informazioni, clicca qui

È possibile scaricare libri? Se sì, come?

Al momento è possibile scaricare tramite l'app tutti i nostri libri ePub mobile-friendly. Anche la maggior parte dei nostri PDF è scaricabile e stiamo lavorando per rendere disponibile quanto prima il download di tutti gli altri file. Per maggiori informazioni, clicca qui

Che differenza c'è tra i piani?

Entrambi i piani ti danno accesso illimitato alla libreria e a tutte le funzionalità di Perlego. Le uniche differenze sono il prezzo e il periodo di abbonamento: con il piano annuale risparmierai circa il 30% rispetto a 12 rate con quello mensile.

Cos'è Perlego?

Perlego è un servizio di abbonamento a testi accademici, che ti permette di accedere a un'intera libreria online a un prezzo inferiore rispetto a quello che pagheresti per acquistare un singolo libro al mese. Con oltre 1 milione di testi suddivisi in più di 1.000 categorie, troverai sicuramente ciò che fa per te! Per maggiori informazioni, clicca qui.

Perlego supporta la sintesi vocale?

Cerca l'icona Sintesi vocale nel prossimo libro che leggerai per verificare se è possibile riprodurre l'audio. Questo strumento permette di leggere il testo a voce alta, evidenziandolo man mano che la lettura procede. Puoi aumentare o diminuire la velocità della sintesi vocale, oppure sospendere la riproduzione. Per maggiori informazioni, clicca qui.

Polymeric Foams è disponibile online in formato PDF/ePub?

Sì, puoi accedere a Polymeric Foams di S.-T. Lee, S.-T. Lee in formato PDF e/o ePub, così come ad altri libri molto apprezzati nelle sezioni relative a Technik & Maschinenbau e Chemie- & Biochemietechnik. Scopri oltre 1 milione di libri disponibili nel nostro catalogo.

Informazioni

1 Introduction

Shau-Tarng Lee

Foam Update

DOI: 10.1201/9781003166160-1

Contents

- 1.1 Introduction

- 1.2 Innovations

- 1.2.1 Polypropylene Foam Sheet

- 1.2.2 Elastomeric Foam

- 1.3 Environment: Degradable and Renewable Foam

- 1.3.1 Water-Soluble Foam

- 1.3.2 Renewable-Source Foam

- 1.3.3 Health Care

- 1.4 Machinery Advancement

- 1.4.1 Cooling Design Progression for Foam Extrusion

- 1.4.2 Pressure Mold Foaming for Engineered Polymers

- 1.5 Summary

- References

1.1 Introduction

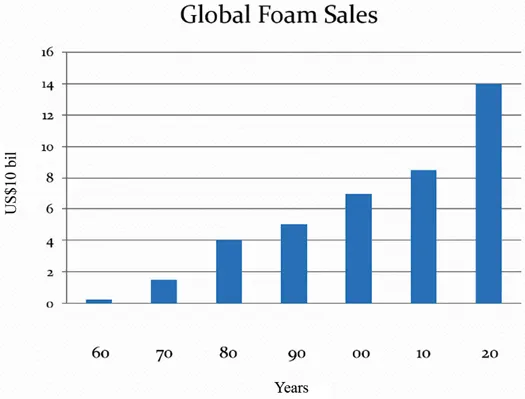

Polymeric foams began its footprints in the 1930s in Europe. World War II greatly fueled technology advancements in machinery design, benefitting polymeric foam production. After the War, technology transfer to civilian applications along with significant research into the mysterious polymeric foam development made tremendous strides in the technology advancement [1,2]. Since then, business began to find in-roads into applications to improve living quality [3]. Figure 1.1 shows a photo of polystyrene (PS) foam log taken in 1949. In the 1960s, foam was recognized in the US and EU markets as a useful product for protection and packaging. The living standard improved. It drew R&D supports from industrial partners to excel manufacturing technology for sustainable business growth. A vivid business model was established. Meanwhile, Japan also joined the methodology development force, which became fruitful in the 1970s and thereafter [4]. The Microcellular technology and the Montreal Protocol to regulate emissions of halogenated hydrocarbon known as chlorofluorocarbon (CFC) were the major events in the 1980s [5,6 and 7]. The former simply opened the academic R&D gate to work closely with industrial R&D not only for business growth but social accountability. For plastics industry, recycle/reuse became a top concern in the 1990s, which was a tougher issue for foam, since it generally required a tighter processing window. When climate change drew global attention in the beginning of the twenty-first century, more pressure was laid on the plastic industry. Foam in food and beverage packaging has been switched to paper-based alternatives. At the same time, foam’s role began to change from visible core product to invisible supportive specialty material. Its consumption continues to increase as illustrated in Figure 1.2 [8]. A quick summary of the foam technology/business development for the last 90 years is provided in Table 1.1.

| Years | Technology | Product | Attribute | Application |

|---|---|---|---|---|

| 1930 | Reactive foaming | PU | Light & rigidity | Military |

| 1940 | Mold foaming | PS, PE | Shock absorption | Flotation |

| 1950 | Extrusion | PS | Thermoforming | Food, packaging |

| 1960 | X-linking, injection mold | PE | Soft & formable | Automotive |

| 1970 | Bead foaming | PS, c-PP | Irregular shape | Cup, packaging |

| 1980 | Microcellular | PS | Inorganic blowing agent | Food |

| 1990 | Extrusion | PET, PP | Branched polymer | Food, box |

| 2000 | Extrusion, molding | PLA | Renewable source | Food |

| 2010 | Nanocellular | PMMA | Low conductivity | Insulation- to be proved |

| 2020 | Mold foaming | TPU | Elasticity | Sports |

In fact, polymer consumption for low-density foam—expansion over 15 times—is less than 10% by weight. Yet its expansion over 15 times—more areas over 20 times due to precision technology—makes it the most visible in the eyes of the consumer and in the waste management chain. The technology focus was turned from how to increase performance/weight ratio before the 1980s to how to reduce its life recycle and carbon footprint in the twenty-first century. From the trend, it is evident that the driving force began with technology optimization up to 1980, then business practice till 2000, and now to customer satisfaction. Innovative and socially accountable operation became the focal point. The merging between Exxon and Mobil in the 1990s and Dow and Dupont in 2016 are good illustrations. Innovation trends are simply turned from technical front to novel applications [9,10]. There is no doubt that innovation and environment are the main thrusts in the existing and new business development for foam. The encouraging part is that foam is not just for density reduction in the commodity markets, but its high internal surface area could be a useful characteristic in the sports, health care, medical, electronics, and cosmetics. Although foam may not be the core technology to promote other peripheral techniques into a solid platform to lead the society forward, transformation into the critical supportive role is crucial for foam to keep a sustainable growth.

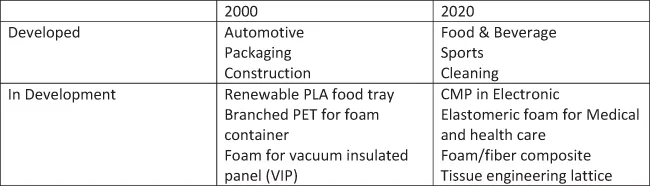

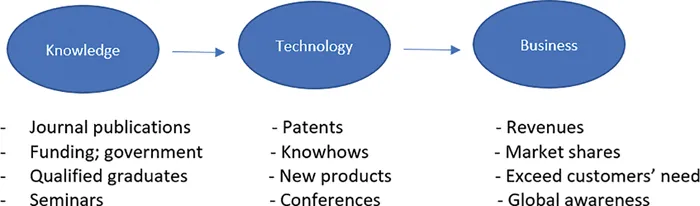

By the end of the twentieth century, most foam technologies, such as foam extrusion, injection molding, bead foam, and x-linked foam, had a very solid foundation. There is not a question that innovative application and environmental merits became the main driver to make the foam product not only a performance material but with a social image in it. This chapter is to address the change in the last decade, when there are incremental improvement in foaming technology and expansion in the application spectrum. Figure 1.3 shows the application comparison between 2000 and 2020. Obviously, customers’ voice played a critical role two decades ago, yet mainly to benefit customers. Now social awareness becomes increasingly important. Social accountability simply raised the bar. The fundamental flow chart as illustrated in Figure 1.4 is the same, but global wellness and awareness continue to drive the demand.

1.2 Innovations

1.2.1 Polypropylene Foam Sheet

PS foam has been known for its wide processing window, high expansion, very good modulus, and excellent thermoformability. It dominated beverage cups, food container, and packaging industries for several decades. The annual consumption reached 120 thousand metric tons in the 1980s. It can be imagined that after 30 times expansion; it became the most visible foam product in the society. Since its decomposition by ultraviolet (UV) was so slow, when combined with its bulkiness, it became an easy target for the environmental group in the early 1990s. Request for alternatives began. Development of high-melt-strength polypropylene a...

Indice dei contenuti

- Cover

- Half Title

- Series Page

- Title Page

- Copyright Page

- Dedication Page

- Table of Contents

- Preface

- Biography

- Contributors

- Chapter 1 Introduction

- Chapter 2 Modification of Rheological Responses under Elongational Flow

- Chapter 3 Bead Foams

- Chapter 4 Foam Injection Molding

- Chapter 5 High-Pressure Foam Injection Molding of Polylactide/Nano-Fibril Composites with Mold Opening

- Chapter 6 Foams in Tissue Engineering

- Chapter 7 Foam in Insulation

- Chapter 8 Advancements in Foam Injection Molding

- Chapter 9 Silicone Foams: A World Different from Other Foams

- Chapter 10 Lab Analysis of Melt-Foaming Behaviors of Long-Chain Branched Polyethylene Terephthalate Using Supercritical CO2 as Blowing Agent

- Chapter 11 Extrusion Foam of Polylactic Acid Using Stereocomplex Crystals

- Chapter 12 Nanocellular Polymers

- Index

Stili delle citazioni per Polymeric Foams

APA 6 Citation

Lee. (2022). Polymeric Foams (1st ed.). CRC Press. Retrieved from https://www.perlego.com/book/3295114/polymeric-foams-innovations-in-technologies-and-environmentally-friendly-materials-pdf (Original work published 2022)

Chicago Citation

Lee. (2022) 2022. Polymeric Foams. 1st ed. CRC Press. https://www.perlego.com/book/3295114/polymeric-foams-innovations-in-technologies-and-environmentally-friendly-materials-pdf.

Harvard Citation

Lee (2022) Polymeric Foams. 1st edn. CRC Press. Available at: https://www.perlego.com/book/3295114/polymeric-foams-innovations-in-technologies-and-environmentally-friendly-materials-pdf (Accessed: 15 October 2022).

MLA 7 Citation

Lee. Polymeric Foams. 1st ed. CRC Press, 2022. Web. 15 Oct. 2022.