- 534 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

Materials and Process Selection for Engineering Design

About this book

Introducing a new engineering product or changing an existing model involves developing designs, reaching economic decisions, selecting materials, choosing manufacturing processes, and assessing environmental impact. These activities are interdependent and should not be performed in isolation from each other. This is because the materials and processes used in making a product can have a major influence on its design, cost, and performance in service. This Fourth Edition of the best-selling Materials and Process Selection for Engineering Design takes all of this into account and has been comprehensively revised to reflect the many advances in the fields of materials and manufacturing, including:

- Increasing use of additive manufacturing technology, especially in biomedical, aerospace and automotive applications

- Emphasizing the environmental impact of engineering products, recycling, and increasing use of biodegradable polymers and composites

- Analyzing further into weight reduction of products through design changes as well as material and process selection, especially in manufacturing products such as electric cars

- Discussing new methods for solving multi-criteria decision-making problems, including multi-component material selection as well as concurrent and geometry-dependent selection of materials and joining technology

- Increasing use of MATLAB by engineering students in solving problems

This textbook features the following pedagogical tools:

- New and updated practical case studies from industry

- A variety of suggested topics and background information for in-class group work

- Ideas and background information for reflection papers so readers can think critically about the material they have read, give their interpretation of the issues under discussion and the lessons learned, and then propose a way forward

- Open-book exercises and questions at the end of each chapter where readers are evaluated on how they use the material, rather than how well they recall it, in addition to the traditional review questions

- Includes a solutions manual and PowerPoint lecture materials for adopting professors

Aimed at students in mechanical, manufacturing, and materials engineering, as well as professionals in these fields, this book provides the practical know-how in order to choose the right materials and processes for development of new or enhanced products.

Tools to learn more effectively

Saving Books

Keyword Search

Annotating Text

Listen to it instead

Information

1Product Design and Development in the Industrial Enterprise

1.1 Introduction

- Identification of needs, feasibility study, and concept selection

- System-level design, detail design, and selection of materials and processes

- Testing and refinement

- Manufacturing the product

- Launching the product

- Selling the product

- Planning for its retirement

- Review the main activities of identification of needs, performing a feasibility study, and selecting an optimum concept.

- Discuss the main stages of designing and manufacturing a product.

- Discuss the main activities involved in testing and refining a new product and then launching and selling it.

- Analyze the environmental issues that are involved in making a product and in retiring it.

- Explain the concepts of life cycle costing and the product life cycle.

1.2 Feasibility Study, Identification of Needs, and Concept Selection

1.2.1 Market Research

- The range of features and technical advantages and disadvantages of the existing products, the mechanism of their operation, and the materials and processes used in making them.

- Past and anticipated market growth rate and expected market share by value and volume.

- The number of companies entering and leaving the market over the past few years and reasons for those movements.

- The reasons for any modifications that have been carried out recently and the effect of new technology on the product.

- Patent or license coverage and what improvements can be introduced over the existing products.

- Profile of prospective customers (income, age, sex, etc.) and their needs in the area covered by the product under consideration.

- Ranking of customer needs in the order of their importance.

- Product price that will secure the intended volume of sales.

- How long will it take for the competition to produce a competitive product?

- What is the optimum packaging, distribution, and marketing method?

1.2.2 Customer Needs and Product Specifications

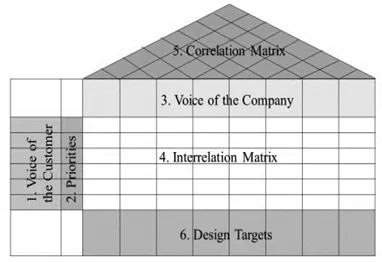

- Voice of the customer is a list of customer requirements from the product. These are usually gathered through conversations, opinion surveys, and market research. Examples of such requirements are shown in Table 1.1 for a cordless power drill for domestic use.

- Prioritized customer requirements and the degree of customer satisfaction with various competing products relative to the different requirements are included in this section. This information is also based on opinion surveys and market research.

- Voice of the company can be a list of the technical parameters, product characteristics, from the point of view of the manufacturer in terms of engineering specifications. These include measurable quantities such as weight, dimensions, level of noise, power consumption, and cost. For example, a specification of “the total weight of the product must be less than 5 kg” can be based on the customer need of a “lightweight product” and the observation that the lightest competing product is 5 kg. Similarly, a specification of “average time to unpack and assemble the product is less than 22 min” can be based on a customer need of “the product is easy to assemble” and the observation that the compe...

Table of contents

- Cover

- Half Title

- Title

- Copyright

- Contents

- Preface to the Fourth Edition

- Preface to the Third Edition

- Preface to the Second Edition

- About the Author

- Chapter 1 Product Design and Development in the Industrial Enterprise

- PART I Performance of Components in Service

- PART II Relationships between Design, Materials, and Manufacturing Processes

- PART III Selection and Substitution of Materials and Processes in Industry

- PART IV Appendices

- Index

Frequently asked questions

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app